Ever heard about a Greenhouse exhaust fan? A ventilation fan is a different description for the type of fans that are used to keep air in circulation and fresh inside greenhouses. One of these fans will do wonders ensuring your plants in the greenhouse grow strong and healthy. How a Greenhouse Exhaust Fan WorksIn this article, we find out more about how greenhouse exhaust fans work. We will discuss what it does to the air, how well we can breath with trees creating fresh air for all of us plants grow big and healthy and safe from danger.

Read more about the teamHave you ever walked into a hot, stuffy greenhouse? It's awkward,Is it not? If air does not flow properly inside, this will happen. This is when a greenhouse exhaust fan comes in the picture by taking fresh air from outside and releasing older, stale air out of it. It also keeps the carbon dioxide we breathe low. If you have to much carbon dioxide, it will actually slow your plant growth. Having a greenhouse exhaust fan in place is the best way to ensure that your plants are receiving proper ventilation so they can grow, and thrive.

Just like ourselves, plants love to breathe in fresh air! Better growth of plants- when a greenhouse has properly installed exhaust fans, it supports faster and stronger plant growth. Fresh air supplies a steady flow of essential nutrients and water through the soil that should be particularly beneficial for plant life. It also maintains the ideal temperature and humidity for specific plants If your cultivated plants are not growing as well for you at least likely it could be time to consider investing in a quality greenhouse exhaust fan.

Healthy plants rely greatly on humidity and temperature. Overly moisture - plants become weak and wilt. On the side of too little humidity, plants can become susceptible to sickness. Temperature is no different. Too much heat or cold will be the reason plants may refuse to grow and live their best lives. It maintains the humidity as well as temperature in your greenhouse. This is the machine that will kick out hot air during summer to keep everything refreshed cool and pull warm earth from outside when winter so your plants don't get cold. The fan will also circulate drier air and maintain the humidity at a suitable level critical for plants to grow healthily.

One of the best things about a greenhouse exhaust fan is that it will help you save money for energy costs. That works coolant like a charm, without using much electricity and just keeping the temperature/humidity within an acceptable range. No getting extra heaters or coolers up and running, which will save you an absolute mint on the bills of heating alone. Simply by using the fan to improve air movement, you can operate your greenhouse more effectively and save money in the process. Your plants will say thank you.

Greenhouse exhaust fan last but not least is a major boon to protect your plants from diseases and pests.cvtColor(3) Mold and bugs like nothing more than to grow in newly nasty groundless with stale air. But the fan prevents this by moving fresh air and not allowing for parts of the grow area to become locations where bad organisms will settle within. These parasites will also be kept away from your greenhouse. This, in turn produces a more healthful ecosystem within which your vegetation can also develop all through the year.

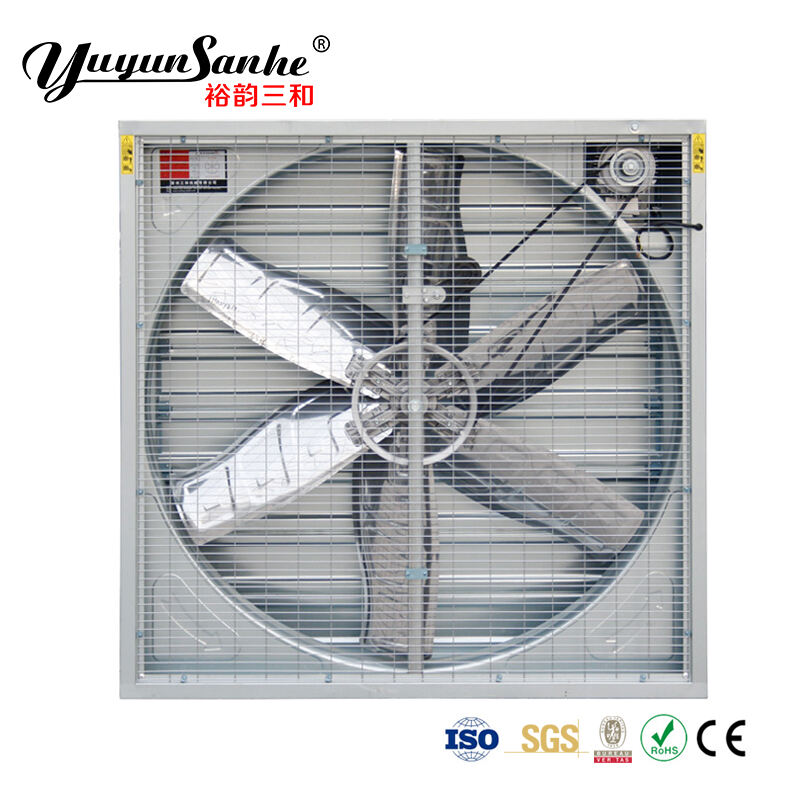

The fan plates are all composed of 275g/m2 hot-dip galvanized sheet. It is purchased from the world-renowned greenhouse exhaust fan "Shougang Group" that not only guarantees product quality but also cuts production costs. Mitsuboshi belt imported from Japan to ensure high-quality and service life. Krupp 430BA Stainless Steel blades, with an enormous air volume and great efficiency. No deformation, no dirt, beautiful and durable. The 304 2B Stainless Steel Blades can be personalized. Flange and belt pulley are constructed of high-strength aluminum and magnesium alloy through die-casting. It is light weight and vibration-free, as well as strong, and with no breakage. All parts are manufactured by CNC efficient manufacturing that guarantees the highest quality, attractive design and top of the line. Yuyun Sanhe, Siemens, WEG, ABB, and WEG motors are available. Voltage and Frequency can be changed.

We have a greenhouse exhaust fan manufacturing machine that is efficient and automation. The cooling pads produced are corrugated uniformly, have strong structural strength and can absorb water efficiently. The corrugated papers have been specially treated to have high durability and resistance to corrosion. It also resists mildew. Water absorption and permeability are excellent, no water drift, will ensure that water is evenly absorbed by the entire cooling pad wall. The stereoscopic design is specific and provides the biggest surface area for evaporation to exchange heat between water and air, the efficiency of evaporation is high. Safety Energy saving Environmental protection, cost-effective and applicable. Standard production 600mm wide cooling pad requires at least 86 sheets. Frames made of aluminum or stainless steel frame galvanized sheet frame and PVC frame are options.

Shandong Yuyun Sanhe Machinery Co. We are the nation's leading manufacturer of equipment for ventilation. Our manufacturing equipment is controlled digitally and we insist that each error is less than 0.03mm so that we can guarantee the complete interchangeability of our products. We make 95% of our own parts which lowers the cost of production, ensures product quality and leads the way in cost-performance. Our super design team is comprised of more than 20 professionals with over greenhouse exhaust fan of design and manufacturing expertise. To ensure that there are no defects All products have been improved at every stage of production, from drawing to the production, from the production to a drawing, and finally by making improvements to the drawing, we can move onto mass production. We have the professional sales staff that is able to plan the purchase scheme for customers, reduce transportation costs, and improve customer profit margins. A perfect after-sales service system gives our customers peace of mind. concerns.

greenhouse exhaust fan company is equipped with the latest Feed Silo Production Equipment that is highly precise and automated. The body of the silo is made from 275g/m2 hot-dip-galvanized sheet, while the screws used are 8.8-level high-strength hot-dip galvanized bolts. These bolts are immune to oxidation, corrosion, and high temperatures, and have longevity and are able to withstand severe storms. The silo is comprised of the silo silo lid as well as the mounting ladder and the silo leg. The parts are manufactured using precision molds and advanced laser technology that is completely in line with the drawing design. They are then subjected quality checks in order to make them more consistent and precise.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802