First, it helps to keep the chickens healthy. Heat stress — Chickens are also prone to something that is called heat stress when it gets too hot out. This occurs when their systems overheat to the point where they are unable to disperse heat effectively. When heat stress occurs, the chickens can feel very unwell or even die if it gets severe. Having a really effective exhaust fan, though, means that the air circulates well and makes it more comfortable to breathe for your birds.

The good exhaust fan for chicken coop should be another reason why the chickens can lay more eggs or grow more meat. It might prompt an easier, healthier way of life where the chickens can bring up themselves by breathing air that is clean and refreshing. This means they will now become larger and stronger. This is good for the farm as healthy chickens lay more eggs or give better meat. Therefore, a good exhaust fan is essential for ensuring that the chickens can produce as much work.

The third reason a good exhaust fan will help you save cash. When the air is hot, chickens must spend more energy to maintain a cooler body temperature. That means they eat more and drink, which can cost the farm a lot of money. But when a good exhaust fan is in place, you can have the air aforementioned moving around to keep your chickens cool without tearing apart their feed! This aging however may be oriented for lesser prices of their food and also water in the future.

Caring for Your Exhaust FanOne of the simplest things you can do to keep your exhaust fan in tip-top shape is to clean it on a regular basis. The fan blades may get dirty with the dust, therefore becoming difficult to move. Dust on the blades can lead to more energy used by the fan and not work as well it would be able. And that is why it must be kept clean around the fan blades and also you need to wipe off this dirt on the same so as not get any problem of functioning.

The last part of the check also involves checking that your exhaust fan just works, and in particular its motor. The main job of a fan is to cool, and the motor does just that by making it run. If you have a bad motor, the fan will not work correctly. Therefore you need to check the engine consistently and confirm it is in a good working condition. This ensures that you prevent small issues from ever getting big to start with.

While installing a reliable exhaust fan is good, ultimately we would want to have our backup plan in case it breaks down. If the fan all of a sudden stops working, what is your plan for those chickens so they do not get too warm. That may involve having extra fans or a generator on standby in the event that the power goes. One key to remember is having a backup plan in place at your home, so as not too over exert yourself moving the chickens around.

Automatic controls is the way to go if you wish for a modern system because this will conserve energy. The ventilation can be moderated by these controls based on the temperature or humidity in side of a barn. Now the system never consumes more energy than is actually necessary, so chickens are always happy with their conditions of keeping — this promotes rapid weight gain.

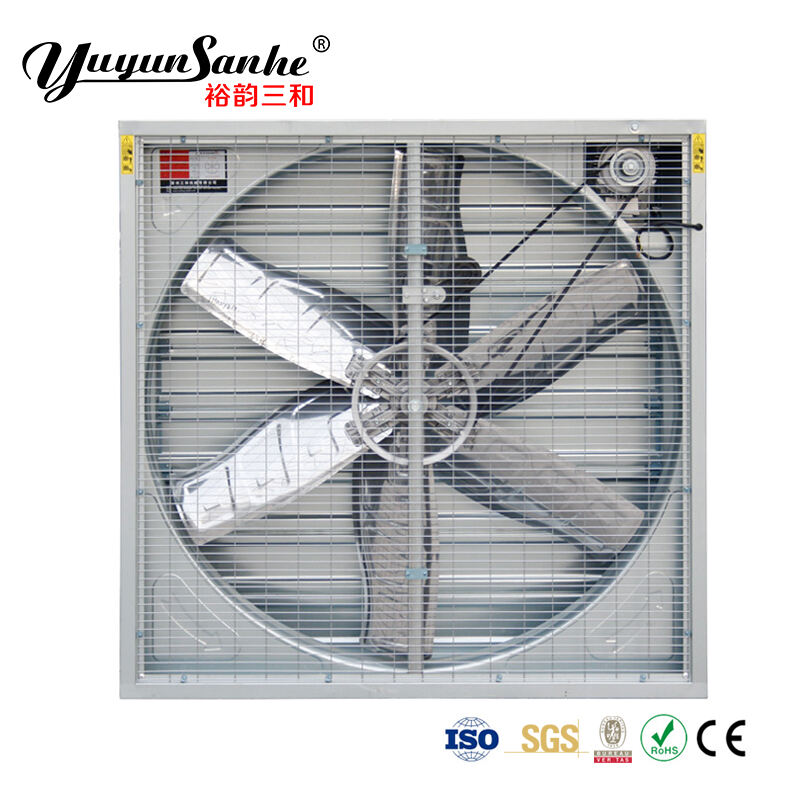

The fan plates are all made of 275g/m^2 chicken farm exhaust fan. It is directly purchased from the famous Chinese steel company "Shougang Group", which does not just guarantee the quality of the product but also helps reduce production costs. Mitsuboshi belt is imported from Japan to ensure high-quality and longevity of service. Krupp 430BA Stainless Steel blades, with big air volumes and high efficiency. No deformation, no dirt, beautiful sturdy. 304 2B Stainless Steel blades can also be customized. Die-casting creates belt pulleys and flanges constructed from high-strength alloys made of magnesium and aluminum. They are light and have low vibration. They also have high strength, and will not break. The entire assembly is made by CNC automated manufacturing, which guarantees high-end quality, stunning appearance, and a leading position in the market. Yuyun Sanhe motor, Siemens motor, WEG motor and ABB motors are available. Voltage and Frequency can be adjusted.

Our company has advanced Cooling Pad Production Machine, precise computer control high automation, high efficiency in production, the output cooling pad features chicken farm exhaust fan, high structural strength and high water absorption. The corrugated papers have been specially treated to have high quality and strength, as well as resistance to corrosion. It also resists mildew. Water absorption and permeability are excellent without water drift will ensure that water is evenly absorbed by all of the cooling pad's wall. The stereoscopic design offers the highest rate of evaporation for heat exchange between air and water. As per the standard length of 600mm cooling pad consists of more than 86 sheets. Frames made of aluminum and stainless steel frame galvanized sheet frame and PVC frame are options.

Our company has advanced chicken farm exhaust fan with high production automation and high precision. The silo is composed of 275g/m2 hot dip galvanized sheet. All screws are made of 8.8-level high-strength hot-dip galvanized bolts, which are resistant to corrosion, anti-oxidation, high-temperature resistance and high strength and long-lasting, and can withstand a hefty storm. The feed silo is mainly composed of silo body, silo cover, mounting ladder and silo legs. Each component is manufactured in strict accordance with drawing design by using advanced laser equipment and precise molds which are then subjected to rigorous quality inspections to make each component more standard and precise in its size, and more convenient to install to ensure easy installation and operation.

Shandong Yuyun Sanhe Machinery Co. is the largest domestic manufacturer of cooling and ventilation equipment, we have the most chicken farm exhaust fan of production equipment, all of which use digital control. Additionally, the errors of each process are restricted to less than 0.03mm to ensure that the interchangeability of our product parts is 100100. We manufacture 95% of our own components, which reduces production costs and assures the highest quality of product and is a leader in the industry in cost efficiency. We have a top design team, more than 20 years of expert production and design experience. Every product has been refined from drawing to production from drawing to production, and from drawing improvement to mass production to ensure that the rate of product defects is zero. Our sales professionals will help you plan your purchase for you, reduce transport costs and boost profit margins. The perfect after-sales support system let our customers no worry about their purchases.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802