Centrifugal exhaust fans that produce whirring, whooshing and buzzing noises when you need to keep the air fresh in your home or at work. Such fans operate manually using nothing but a simple and very old concept of physics : the centrifugal force, which is defined as nature's tendency to pull objects away from the center. They bring air in and redirect it out away from the building, making things more hospitable. Understanding what benefits one can get from these fans and how they work may not just be an advantage householders but the businesses too.

The centrifugal fan acts as a vacuum, which is an air field with less amount of air than neighboring spaces. As with any fan, this vacuum sucks air into from the front of it so is highly efficient in that respect and will move a lot of air around (so you should always watch your hat). This fan pulls the water using suction and discharges it outside. The fan rotates at high speed when air goes into inside The spinning blades pushes the air out of a compartment called an exhaust. Centrifugal exhaust fan moves air hence this movement of air is known as centrifug(al) force. The higher the speed of spinning your blades, the more air it mounds up andthe forceful action helps to clear out unwanted particles from around fingers.

The centrifugal exhaust fans can good for those who want to improve their home indoor air|-------------------------------------------------------------------------- These fans can remove bad things from the air, like smoke and dust - or allergens (AL-ur-genz) for short.Bot particles are also small things that can make people want to sneeze or get sick. The fans expel this dangerous substances to the exterior, where these do not pose problems. They also aid in removing stagnant air that causes problems such as mold and mildew. Mold and mildew make people sick, harm their immunity system as well cause allergies so it is crucial to keep them away from us.

So, when selecting centrifugal exhaust fan you need to consider that what your specific requirements are and where do you live in. In this case, if you are living in a humid place (that means there is lot of moisture content present in the air), then you may opt for large volume cooling procedres that ensure rapid movement of cool surface area. This reduces the humidity and makes your house feel cooler. Alternatively, if you stay in a location where there is high pollution or poor air quality look for a fan that features an unique filter called as HEPA Filter. This category of filter is created to entrap smallative and toxic tained particles present in the air, preventing them from staying inside.

Centrifugal exhaust fans are designed as an energy efficient way to move air in a space, utilizing up to 30% less electricity than similarly-rated axial options. This not only saves you money on your energy bills, it also better for the environment. Select a fan with an excellent Energy Star rating for the energy saver Another great way to save energy is by maintaining your fan clean and in good condition. This includes routine cleaning of your blades and filters, inspecting the motor to ensure smooth operation, as well ensuring proper installation in place for the type you selected.

Centrifugal exhaust fans are not only for homes, but very literally they work best in factories and commercial spaces such as: restuarants. In this way, these fans are removing hazardous gases in the form of fumes and smoke by maintained its quality air which is suitable for workersafety. Centrifugal fans, for example are used to remove the smoke and steam produced by cooking process in commercial kitchens. This in turn actually increases air quality but also helps prevent a grease fire among other contaminants that can build up over time.

We have a cooling pad production machine that is efficient and automation. The cooling pads we produce are corrugated in a uniform manner, have strong structural strength and are able to absorb water effectively. Corrugated paper is treated to provide excellent structural strength for corrosion resistance, anti-mildew properties and long service life. Water absorption and permeability are excellent with no water drift will ensure that water gets evenly through the entire wall of the cooling pad. The stereoscopic design provides the highest rate of evaporation for heat exchange between air and water. A centrifugal exhaust fan as per standard, width of 600mm cooling pad requires more than 86 sheets. Frames made of aluminum frames, stainless steel frames, galvanized sheet frame, and PVC frames are all available.

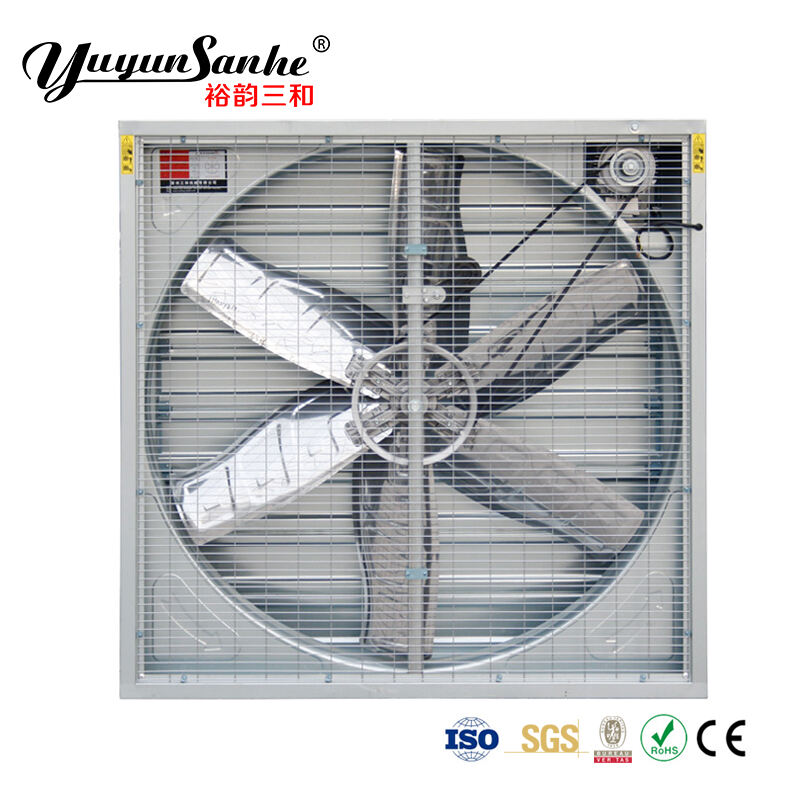

Shandong Yuyun Sanhe Machinery Co. is the largest domestic manufacturer of cooling and ventilation equipment, we have the most centrifugal exhaust fan of production equipment, all of which use digital control. Additionally, the errors of each process are restricted to less than 0.03mm to ensure that the interchangeability of our product parts is 100100. We manufacture 95% of our own components, which reduces production costs and assures the highest quality of product and is a leader in the industry in cost efficiency. We have a top design team, more than 20 years of expert production and design experience. Every product has been refined from drawing to production from drawing to production, and from drawing improvement to mass production to ensure that the rate of product defects is zero. Our sales professionals will help you plan your purchase for you, reduce transport costs and boost profit margins. The perfect after-sales support system let our customers no worry about their purchases.

Our company owns advanced Feed Silo Production Equipment that is extremely precise and automated. The silo is composed of centrifugal exhaust fan hot dip galvanized sheet. All screws are made of 8.8-level high-strength hot-dip galvanized bolts that are anti-oxidation and corrosion resistant. They also have high-temperature resistance and high strength and long-lasting, and can withstand a strong storm. The silo is made up of the silo, the silo lid, the mounting ladder, and the silo leg. These components are created using high-quality molds, precision tools and laser technology that is completely in line with the drawing design. Then, they undergo strict quality checks to make them more standard and precise.

The fan plates are all composed of centrifugal exhaust fan hot-dip galvanized sheet. It is directly bought from the renowned Chinese steel manufacturer "Shougang Group" This not only guarantees product quality but also cuts production costs. Mitsuboshi belt is directly imported from Japan for its high-quality and long-lasting service. Blades material is Krupp self-cleaning 430BA Stainless Steel, large air volume with high efficiency and no deformation, so no dust, gorgeous and durable. 304 2B Stainless Steel Blades can be custom-made. Die-casting creates belt pulleys and flanges made from high-strength alloys of magnesium and aluminium. They are lightweight, have low vibration, high strength, and will not break. All parts are produced by CNC efficient production, gorgeous appearance, quality assurance and are among the top in the market. Yuyun Sanhe motor, Siemens motor WEG motor, ABB motor are optional. Voltage and Frequency are customizable.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802