environment. livestock feeder are often seen in factories where products are manufactured, warehouses which house a variety of commodities and even workshops inside which items are constructed by the workers working therein-plug fan manufacturers.

Along with cooling down the region, industrial exhaust fans also keep walls dry and warm. automatic feeder is especially key in areas like reclining track working environment where machines can create significant measures of warmth or around harmful chemicals that deliver unpleasant smells and lethal exhaust. Exhaust fans help workers to breathe fresh air and thus feel healthier.

These fans work tirelessly to evacuate the toxic fumes from inside, so that everyone within and without are safe. GM: poultry farm equipment was a wise recommendation just for the reasons of health and safety with all those harmful bunny chemicals, when you make it sound like that breathing thing is good then effective ventilation systems are no longer optional but necessary.

It helps to efficiently remove and vent out the stale air from kitchens, bath rooms etc bringing in outside fresh clean air. This feeding pan for broiler is important because this would help in making the place better for everyone inside, leading to a peaceful and productive work environment.

Workers will be better in work with an industrial exhaust fan available at their workspace. animal feeder is about not only making workers comfortable but helping them concentrate on their rallies, thanks to breathable air and adequate lighting.

Our company has advanced Cooling Pad Production Machine, precise computer control high automation, high efficiency in production, the output cooling pad features Industrial exhaust fan, high structural strength and high water absorption. The corrugated papers have been specially treated to have high quality and strength, as well as resistance to corrosion. It also resists mildew. Water absorption and permeability are excellent without water drift will ensure that water is evenly absorbed by all of the cooling pad's wall. The stereoscopic design offers the highest rate of evaporation for heat exchange between air and water. As per the standard length of 600mm cooling pad consists of more than 86 sheets. Frames made of aluminum and stainless steel frame galvanized sheet frame and PVC frame are options.

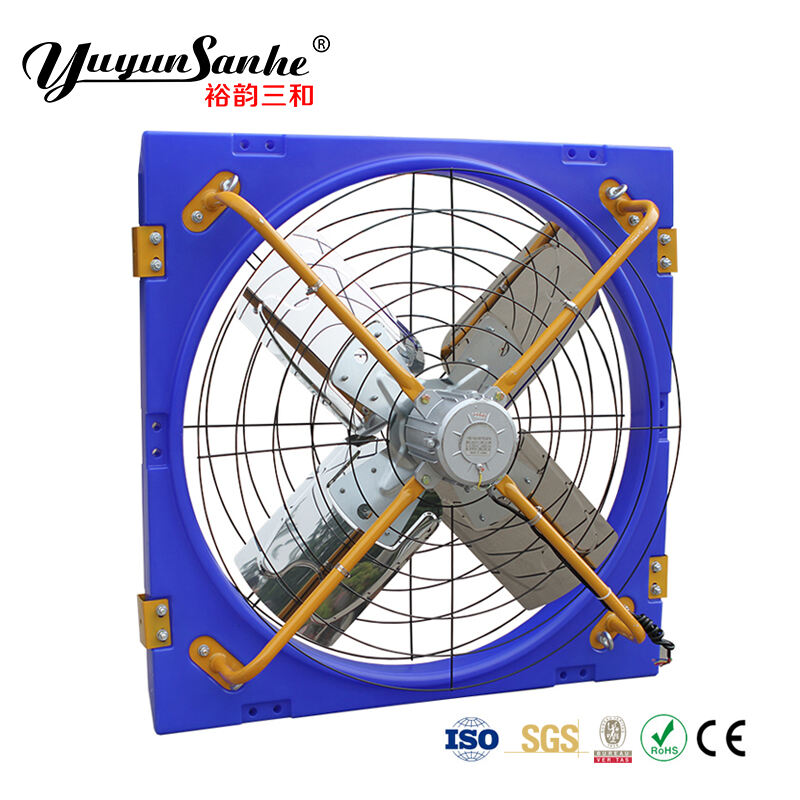

The fan plates are all made of 275g/m^2 Industrial exhaust fan. It is directly purchased from the famous Chinese steel company "Shougang Group", which does not just guarantee the quality of the product but also helps reduce production costs. Mitsuboshi belt is imported from Japan to ensure high-quality and longevity of service. Krupp 430BA Stainless Steel blades, with big air volumes and high efficiency. No deformation, no dirt, beautiful sturdy. 304 2B Stainless Steel blades can also be customized. Die-casting creates belt pulleys and flanges constructed from high-strength alloys made of magnesium and aluminum. They are light and have low vibration. They also have high strength, and will not break. The entire assembly is made by CNC automated manufacturing, which guarantees high-end quality, stunning appearance, and a leading position in the market. Yuyun Sanhe motor, Siemens motor, WEG motor and ABB motors are available. Voltage and Frequency can be adjusted.

Shandong Yuyun Sanhe Machinery Co. We are the nation's leading manufacturer of equipment for ventilation. Our manufacturing equipment is controlled digitally and we insist that each error is less than 0.03mm so that we can guarantee the complete interchangeability of our products. We make 95% of our own parts which lowers the cost of production, ensures product quality and leads the way in cost-performance. Our super design team is comprised of more than 20 professionals with over Industrial exhaust fan of design and manufacturing expertise. To ensure that there are no defects All products have been improved at every stage of production, from drawing to the production, from the production to a drawing, and finally by making improvements to the drawing, we can move onto mass production. We have the professional sales staff that is able to plan the purchase scheme for customers, reduce transportation costs, and improve customer profit margins. A perfect after-sales service system gives our customers peace of mind. concerns.

Industrial exhaust fan company is equipped with the latest Feed Silo Production Equipment that is highly precise and automated. The body of the silo is made from 275g/m2 hot-dip-galvanized sheet, while the screws used are 8.8-level high-strength hot-dip galvanized bolts. These bolts are immune to oxidation, corrosion, and high temperatures, and have longevity and are able to withstand severe storms. The silo is comprised of the silo silo lid as well as the mounting ladder and the silo leg. The parts are manufactured using precision molds and advanced laser technology that is completely in line with the drawing design. They are then subjected quality checks in order to make them more consistent and precise.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802