Fans are devices that remove or draw air from one location to another. In fact, fans come in all shapes and sizes - from small desk or table top models to blow a little air into your face up to massive industrial sized installations that can empty the entire contents of a warehouse at high speed. An industrial axial fan is a special type of fan. They have fans created that can push so much air really quick. This makes them ideal for large spaces like factories, warehouses and other big buildings that need a lot of airflow.

Benefits to Businesses Provided by Axial Fans An axial fan, in the case of a business or job site is an indispensable tool for all manner of uses.

These industrial and large scale axial fans are used in industries to regulate the setting of temperature as well humidity. At the sauna or in hot summer, it cools. They also clearly ventilate the room by pushing out built-up hot air and sucking in fresh, cool air from outside. This way, they can act as air circulators particularly during the cold winter when everyone wants to keep warm and cozy all over. This is very essential because it keeps you from sweating buckets and running a heat stroke when its hot, or shivering all-night while experiencing hypothermia during cold times. Comfortable workers are productive workers.

Because axial fans come in all shapes and sizes, they are a highly adaptable tool that can be used for numerous jobs. For instance, some of the fans are better for cooling down large machinery having a heat release while operating. The radiator fans are nice because they help keep the air flow in some areas so that it keeps circulating and does not get stagnant. Clean rooms even have fans of their own design. A clean room is a place they have to keep the air super-clean and other small (dusty) particles out of there. Those fans are to ensure the air quality remains relevantly high, particularly in certain industries like pharmaceuticals (and electronics).

There is the biggest advantage of using industrial axial fan that they save energy as well reduce your electricity bill. They consume a lesser amount power when compared to an alternate variety of industrial fans including centrifugal one and which in turn is not efficient. The other good thing about axial fans is that they are typically a lot quieter than most squirrell (strong pressure) type of blowers. Especially useful in locations that loud sound can be an issue, for example offices or where focus is required. Quieter Working Conditions: In addition to improving productivity, quieter fans also create a better working environment by reducing distractions that can be caused due asert of loud noise.

While they have been used for some time now, and has gone through several evolutions since their inception just think of all the improvements computers have seen, axial fans in-line duct blowers are only becoming more widespread. Technology and design have evolved a lot over the years. Modern axial fans today are vastly improved and much more powerful than before. Part of is it a result from newer materials and unique design onPause(true); For instance, the construction of blades now in modern axial fans is lighter with materials like composites or aluminum. Not only are these materials lighter, they also have a longer life than older materials such as wood and steel - thus enhancing the fans durability.

Shandong Yuyun-Sanhe Machinery Co., Ltd. We are the top industrial axial fan of ventilation equipment. Our production equipment is controlled digitally and we require that each error be less than 0.03mm to ensure an absolute interchangeability. About 95% of the components are manufactured by us which reduces the cost of manufacturing and ensuring the quality of the product and setting the standard for cost performance. We have a highly skilled design team with over 20 years of expert design and production experience. To guarantee zero defects All products have been developed at every stage of production, from sketch to the production, from the process to a drawing, and finally by making improvements to the drawing, we can move onto mass production. Our sales team who can efficiently design the purchase plan for the customer, reduce transport costs and boost profit margins. The perfect after-sales support system will leave our customers with no worries.

Our company is equipped with the latest Feed Silo Production Equipment with high-end production automation and precision. The silo is made of 275g/m^2hot-dip galvanized sheet and all screws are made of 8.8-level high-strength hot-dip galvanized bolts. These are industrial axial fan, anti-oxidation, high-temperature resistance, strong, long service life, and can withstand a strong storm. The silo is comprised of the silo silo lid as well as the mounting ladder and the silo leg. The components are made using high-quality molds, precision tools and laser technology that is completely in line with the drawing design. Then, they undergo strict quality checks to make them more common and precise.

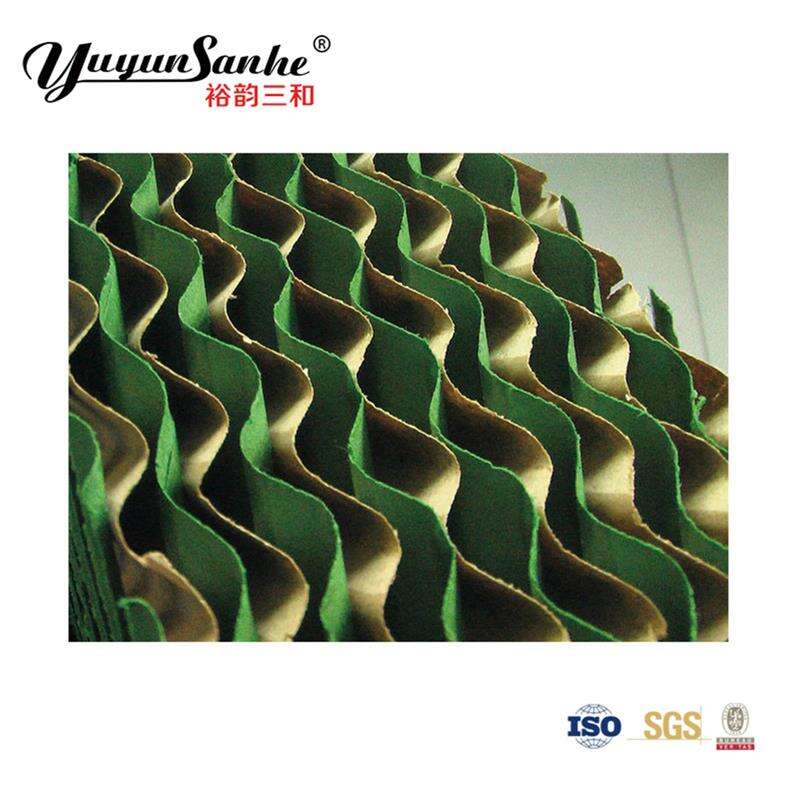

Our company has a state-of-the-art Cooling Pad Production Machine, precise computer control and high automation. It has high efficiency in production, the output cooling pad is uniform in corrugation, a high strength structure and excellent water absorption. Corrugated papers are specially treated, with excellent structural strength for corrosion resistance, mildew resistance and long service life. The water can reach the surface of the cooling pad due to high permeability, water absorption, and zero water drift. A specific stereoscopic structure gives the largest industrial axial fan to exchange heat between air and water. evaporation efficiency is high. Safety, energy saving Environmental protection, cost-effective and practical. Strict production as per standard the 600mm wide cooling pad is 86 sheets. Aluminum frame or stainless steel frame galvanized sheet frame, and PVC frame are available.

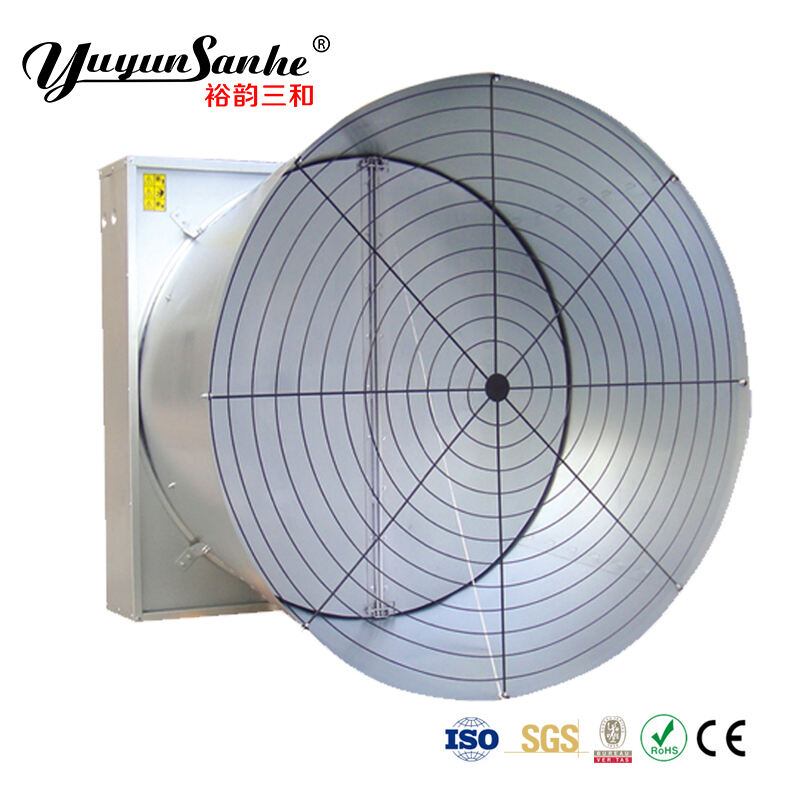

All fan plates are constructed from hot dip galvanized sheets of 275g/m2, which we directly purchase from "industrial axial fan" the most well-known Chinese steel manufacturer. This is not just a guarantee of the quality of our products, but also reduces the cost of production. Mitsuboshi belt is imported from Japan to ensure quality and long-lasting service. Krupp 430BA Stainless Steel blades, with an enormous air volume and great efficiency. No deformation, no dirt, stunning, durable. The 304 2B Stainless Steel Blades can be customized. Belt pulleys and flanges are constructed of high-strength aluminum and magnesium alloy by die-casting, light weight and vibration-free, as well as high strength and no breakage. All components are manufactured using CNC streamlined production, excellent quality control, attractive appearance leading the market. Yuyun Sanhe, Siemens, WEG, ABB, and WEG motors are readily available. The frequency and voltage can be adjusted.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802