We need Air to breathe, the oxygenicide. We all need some fresh air to breathe, so that we are kept alive and happy. We know how our bodies feel when they have to work harder - and we also can imagine the effects of what clean air would do for us. It is common that the air in our room starts feeling suffocating and gets some foul smell. That happens when fresh air is not being allowed in as drafts are continually recirculated. There are ventilation systems that remove bad air well. They can make you feel tired, or even sick if your room does not have one. If the air quality in your home is not maintained properly you may have low mood and find it very difficult to complete both schoolwork as well as play time.

One of the Solutions for Fresh Air From out side Axial Flow Exhaust fan. Ventilation fan : This blow out the bad air from room. It only pushes air through one direction front to back. This sucks it pulls the air from your room and blows outside so that you will feel cool. An axial flow exhaust fan will provide you with a cozy room where none shall distract you, neither for your studying nor playing!

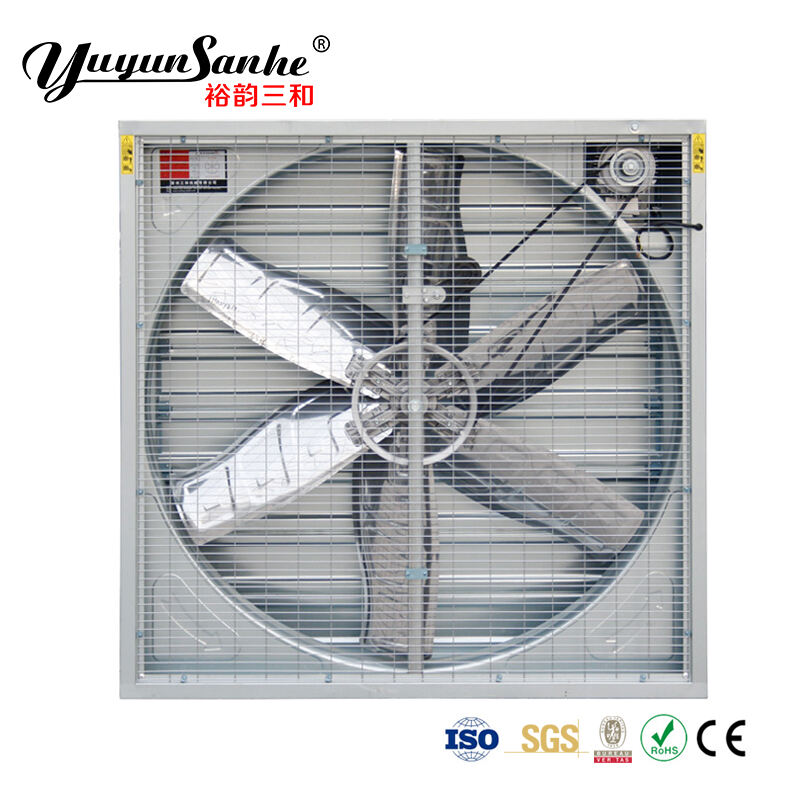

Air always flows in the same direction inside an axial flow exhaust fan. They push and air into the fan and out in reverse of how it was brought so, outward. The fan face had blades in airplane prop design. It all circles around a core, the center line from which air is being forced out of. This makes the fan one of the most powerful, so it provides amazing results in circulating fresh air throughout your environment.

Construction of Axial Flow Fans:The axial flow fans consist of a propeller or tubaxial fan. Propeller fan transfers air from one site to another whereas tubaxial fans transfer air through ducts. The tubaxial fan is nsually used in big buildings like hospitals and hotels where a lot of fresh air circulation needed. Each type of fan are designed to fit in differnt spaces and needs there by allowing you choose the perfect one easily

Comfort aside, you simply cannot take the risk by not using an axial flow exhaust fan. This type of fan is required if you have gas appliances as stoves, or heaters. Gas appliances produce carbon monoxide, a dangerous gas that you cannot see or smell. It can cause you to feel ill, and potentially kill. An axial flow exhaust fan can push carbon monoxide out from your house to the outdoor, keeping you and family safe. This is important for a number of reasons, and it all starts with your health and safety.

These fans also help in places where there are uses of chemicals. They aid in keep away dangerous gases that might make you stay, hard to breathe. An axial flow exhaust fan is a very practical solution if you often work with paints, cleaners and other products that can be rather stinging.

If you wish to enhance the air high quality in your home and also workplace, then it is advisable for all individuals that they need to obtain axial flow exhaust fans. This is what we call an exhaust fan which helps in taking out of bad air and bringing freshness inside the house. They are simple to put up and use-and can even save you money when it comes to energy costs, all while maintaining the health of yourself as well your loved ones. A fan like this can make a big difference!

The fan plates are all composed of 275g/m2 hot-dip galvanized sheet. It is purchased from the famous Chinese steel company "Shougang Group" This does not just guarantee the quality of the product but also reduces production costs. Mitsuboshi belts are imported directly from Japan to ensure quality and lasting service. Blades materials are Krupp self-cleaning 430BA Stainless Steel, large air volume and high efficiency with no deformation and no dust, beautiful and sturdy. The axial flow exhaust fan can be personalized. Flange and belt pulley are made of high-strength magnesium-aluminum alloy made by die casting, which is lightweight weight and vibration-free, as well as strong, and with no breakage. All components are made using CNC automated manufacturing, which guarantees the highest quality, attractive appearance, and a leading position in the market. Yuyun Sanhe motor, Siemens motor WEG motor and ABB motor are also available. Voltage and Frequency are customizable.

We have a axial flow exhaust fan manufacturing machine that is efficient and automation. The cooling pads produced are corrugated uniformly, have strong structural strength and can absorb water efficiently. The corrugated papers have been specially treated to have high durability and resistance to corrosion. It also resists mildew. Water absorption and permeability are excellent, no water drift, will ensure that water is evenly absorbed by the entire cooling pad wall. The stereoscopic design is specific and provides the biggest surface area for evaporation to exchange heat between water and air, the efficiency of evaporation is high. Safety Energy saving Environmental protection, cost-effective and applicable. Standard production 600mm wide cooling pad requires at least 86 sheets. Frames made of aluminum or stainless steel frame galvanized sheet frame and PVC frame are options.

Our company has advanced axial flow exhaust fan with high production automation and high precision. The silo is composed of 275g/m2 hot dip galvanized sheet. All screws are made of 8.8-level high-strength hot-dip galvanized bolts, which are resistant to corrosion, anti-oxidation, high-temperature resistance and high strength and long-lasting, and can withstand a hefty storm. The feed silo is mainly composed of silo body, silo cover, mounting ladder and silo legs. Each component is manufactured in strict accordance with drawing design by using advanced laser equipment and precise molds which are then subjected to rigorous quality inspections to make each component more standard and precise in its size, and more convenient to install to ensure easy installation and operation.

Shandong Yuyun-Sanhe Machinery Co., Ltd. We are the leading domestic manufacturer of equipment for ventilation. Our manufacturing equipment is digitally controlled, and we insist that each error be less than axial flow exhaust fan to ensure an absolute interchangeability. We produce 95% of our own parts that reduces production costs, guarantees product quality and sets the standard in the way in cost-performance. We have a super design team with over 20 years of design and production experience. To ensure zero defect rates All products have been developed at every stage of production, from drawing stage to production, from production to drawing, and finally after drawing improvements, to mass production. Our experienced sales staff will help you plan your purchase for you, reduce transport costs and improve profits. And the perfect after-sales service system allows our customers to have no worries.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802