Did you ever wonder how huge buildings or factories get rid of smells and bad air? In one word, These kind of company uses FRP exhaust fan! These High-Performance fans are the heavy-duty stuff and designed to operate efficiently even in rough environments. Read this article to get an in-depth tour of FRP exhaust fans, their components and how they work simultaneously making more durable than the regular FRP products which is why are they so reliable.

The acronym "FRP" itself stands for Fiberglass Reinforced Plastics. It is an extreme sturdy material and won't decay from heat or chemicals. So, FRP exhaust fans are ideal for factories and big buildings in which there may be some pollution in the air. In particular, these are high-velocity fans that have been specifically engineered to push large volumes of air at a fast pace so instead of your unit's internal atmosphere becoming bogged down with stale and unclean air this fan continues to draw in fresh clean uncontaminated mouthfuls.

Maybe you have a really bad smell and at that moment, the only one thing in your hopes is to stop feeling it. Breathing in bad smells, smoke and harmful chemicals are hazardous to your health. For this purpose, FRP exhaust fans are used! They achieve this by simply removing the old, stale air from within a space and replacing it with cleaner outdoor air. This, in turn, promotes a healthier environment for the individuals who are inside of it. The fan creates the necessary air flow for breathing while if it did not work than after a few hours your home can become filled with toxic gases, so this is crucial.

An FRP Exhaust Fan Will Stand The Test Of Time These fans do not corrode, unlike metal fans that can rust and decompose in wet or humid environments. That is fiberglass and it can be tough as nails -- standing up to harsh chemicals, even withstand extreme temperatures. As a result, they are able to continue doing their job even in difficult conditions. It also helps FRP Fans in being light weight, aiding ease of installation and re-location.

Trust in Your Equipment When running a big factory or building, trust is key with your equipment. The reason many people select FRP exhaust fans is that they are very reliable. They can also be bought separately, as performance fans are probably the best thing you can get if your looking solely for longevity and working without issue day in and day out. This is very important to maintain the nature of air and keep it safe for all. You do not want bad air quality due to fan issues.

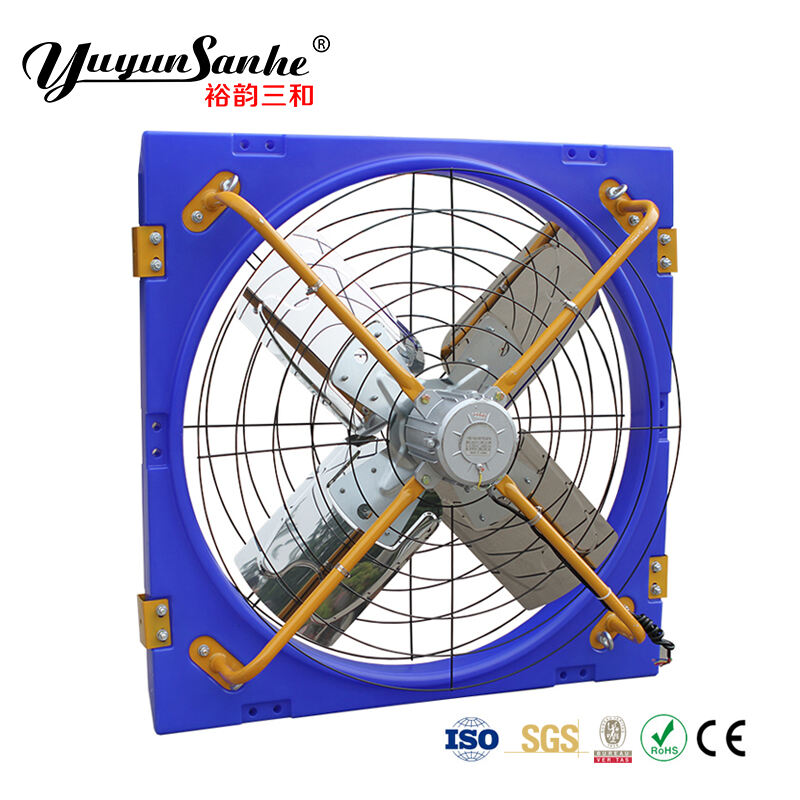

Shandong Yuyun Sanhe Machinery Co. is the largest domestic manufacturer of cooling and ventilation equipment, we have the most frp exhaust fan of production equipment, all of which use digital control. Additionally, the errors of each process are restricted to less than 0.03mm to ensure that the interchangeability of our product parts is 100100. We manufacture 95% of our own components, which reduces production costs and assures the highest quality of product and is a leader in the industry in cost efficiency. We have a top design team, more than 20 years of expert production and design experience. Every product has been refined from drawing to production from drawing to production, and from drawing improvement to mass production to ensure that the rate of product defects is zero. Our sales professionals will help you plan your purchase for you, reduce transport costs and boost profit margins. The perfect after-sales support system let our customers no worry about their purchases.

The fan plates are all composed of 275g/m2 hot-dip galvanized sheet. It is purchased from the world-renowned frp exhaust fan "Shougang Group" that not only guarantees product quality but also cuts production costs. Mitsuboshi belt imported from Japan to ensure high-quality and service life. Krupp 430BA Stainless Steel blades, with an enormous air volume and great efficiency. No deformation, no dirt, beautiful and durable. The 304 2B Stainless Steel Blades can be personalized. Flange and belt pulley are constructed of high-strength aluminum and magnesium alloy through die-casting. It is light weight and vibration-free, as well as strong, and with no breakage. All parts are manufactured by CNC efficient manufacturing that guarantees the highest quality, attractive design and top of the line. Yuyun Sanhe, Siemens, WEG, ABB, and WEG motors are available. Voltage and Frequency can be changed.

Our company is frp exhaust fan with the latest Feed Silo Production Equipment with high production automation and high precision. The silo is composed of 275g/m2 hot-dip galvanized sheet. All screws are made from 8.8-level high-strength hot-dip galvanized bolts that are resistant to corrosion, anti-oxidation, high-temperature resistance and high strength, long service life, and can withstand a hefty storm. The silo consists of the silo, silo lid, mounting ladder and silo leg. Each component is manufactured strictly in accordance with drawing design by using advanced lasers and molds that are precision which are then subjected to rigorous quality inspections to make each element more standard, more precise in size, and more convenient to install to ensure easy installation and operation.

Our company has advanced Cooling Pad Production Machine, precise computer control high automation, high efficiency in production, the output cooling pad features frp exhaust fan, high structural strength and high water absorption. The corrugated papers have been specially treated to have high quality and strength, as well as resistance to corrosion. It also resists mildew. Water absorption and permeability are excellent without water drift will ensure that water is evenly absorbed by all of the cooling pad's wall. The stereoscopic design offers the highest rate of evaporation for heat exchange between air and water. As per the standard length of 600mm cooling pad consists of more than 86 sheets. Frames made of aluminum and stainless steel frame galvanized sheet frame and PVC frame are options.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802