By keeping poultry ventilation fans working in good order, farmers have a significant tool for rearing chickens and additional birds. These fans help to maintain fresh and clean air in the barn (a must for healthy livestock). Fans circulate air inside the barn and remove excess moisture as well as gases such as ammonia, carbon dioxide. Such an air circulation is necessary in order to provide the birds with a safe and healthy living space.

Proper air quality is critical to the birds health. Poor air flow can lead to stagnant pockets that promote the growth of bacteria and viruses. This microbe locates its way to the environment, and when it spreads within flock,it makes sickness of birds. Poultry ventilation fans will aid in keeping the air constantly fresh and clean, thereby lowering the risks of birds getting infected. This gives them the ability to be healthier and prolong their health as they live out their days on the farm.

Farmers must also regulate the barn temperature to maintain a healthy and happy environment for their birds. Too much heat outside will have a detrimental effect on birds as it may cause them to feel stress and avoid having meals. This can retard their development and make them unproductive. While on the other hand, it is a serious cheap to let your birds huddle up when they are cold and this can result in bad feather quality or them getting sick.

Poultry ventilation fans are what helps the barn temperature to be balanced by moving cooled or warmed air throughout a space. It allows the air to circulate which can make the barn a comfortable temperature for your birds and makes no difference what the weather is outside. These fans will also save farmers in heating and cooling costs. This not only aids good health and strength to the birds but also is an advantage of cost reduction for farmers.

The solution to this problem lies in using poultry ventilation fans. They help by sucking out the additional moisture and also toxic gases from barn These fans help save more birds, increase poultry density on a farm and reduce bird death with improved air quality. What this means is farmers can produce more chickens, which gives them a greater income overall.

SequelOwners need instructor fans Different types of fans are available like box fan, wall mounted, bladeless ceiling fan. Every one of those have pluses and minuses, so it is wise to induct the options for farm lands. They will, however, do a good job of researching and understanding what each fan is capable of - in order to make the best choice for their particular need on the farm.

Best practices have demonstrated that installing poultry ventilation fans can save farmers money without sacrificing the condition of their birds. By human quality (controlling installments of oxygen, poor air and a perfect adjustment) the chances for ailment or death among flying creatures will be gigantically diminished. It means lower costs of production and makes the farmers overall results better.

The fan plates are all made of 275g/m^2 poultry ventilation fans. It is directly purchased from the famous Chinese steel company "Shougang Group", which does not just guarantee the quality of the product but also helps reduce production costs. Mitsuboshi belt is imported from Japan to ensure high-quality and longevity of service. Krupp 430BA Stainless Steel blades, with big air volumes and high efficiency. No deformation, no dirt, beautiful sturdy. 304 2B Stainless Steel blades can also be customized. Die-casting creates belt pulleys and flanges constructed from high-strength alloys made of magnesium and aluminum. They are light and have low vibration. They also have high strength, and will not break. The entire assembly is made by CNC automated manufacturing, which guarantees high-end quality, stunning appearance, and a leading position in the market. Yuyun Sanhe motor, Siemens motor, WEG motor and ABB motors are available. Voltage and Frequency can be adjusted.

Shandong Yuyun-Sanhe Machinery Co., Ltd. We are the top domestic manufacturer of ventilation equipment. Our manufacturing equipment is digitally controlled, and we require that each error is less than 0.03mm so that we can guarantee an absolute interchangeability. More than poultry ventilation fans of our components are manufactured by us, reducing the cost of manufacturing as well as ensuring quality product, and leading the world in price performance. Our design team is super-efficient and has more than 20 professional years of production and design know-how. All products have been improved from drawing to production from production to drawing, and from drawing improvement to mass production to ensure that the percentage of defects is zero. Our professional sales team will design your purchase for you, reduce transport costs and increase profits. The perfect after-sales support system let our customers no worry about their purchases.

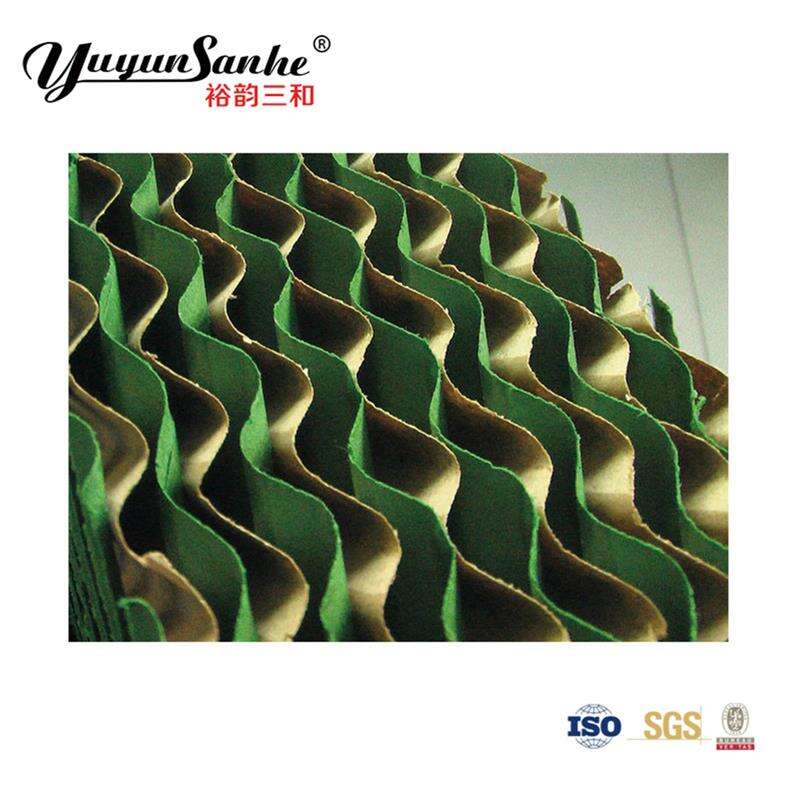

We have a poultry ventilation fans manufacturing machine that is efficient and automation. The cooling pads produced are corrugated uniformly, have strong structural strength and can absorb water efficiently. The corrugated papers have been specially treated to have high durability and resistance to corrosion. It also resists mildew. Water absorption and permeability are excellent, no water drift, will ensure that water is evenly absorbed by the entire cooling pad wall. The stereoscopic design is specific and provides the biggest surface area for evaporation to exchange heat between water and air, the efficiency of evaporation is high. Safety Energy saving Environmental protection, cost-effective and applicable. Standard production 600mm wide cooling pad requires at least 86 sheets. Frames made of aluminum or stainless steel frame galvanized sheet frame and PVC frame are options.

Our company is equipped with the latest Feed Silo Production Equipment that is extremely automated and precise. The silo is composed of hot-dip galvanized sheets weighing 275g/m2 and all screws are made of 8.8-level high-strength hot-dip galvanized bolts, which are poultry ventilation fans, corrosion-resistant, high-temperature resistance, high strength and have a long service life and can withstand a strong storm. The silo consists of the silo, silo lid mounting ladder, silo leg. The parts are produced by using precise molds and the latest laser technology in complete compliance with the drawing design. They are then subjected quality tests to ensure that they are standard and accurate.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802