Have you heard of a broiler feeder? A broiler feeder is a particular mechanized instrument farmers use to feed poultry birds that are newly born and will be raised for meat production. These chickens are different from other types, since they grow rapidly. In fact, they might even pack on 1 kilogram in only six weeks! Broiler Diet Broilers are rapidly growing and should be fed a diet that enables growth.

Why are broiler feeders so crucial to chicken farmers? That's where broiler feeders come in, they make it easy for farmers to ensure each chicken gets the appropriate quantity of food. But if feed is tabled only one or two will shine while the rest may not get enough to eat. These problems can lead to poor health, uneven growth etc. Broiler feeders ensure that ideal amount of food is supplied to the chicken at a right point and this way broilers are stimulated for healthy growth.

Broiler Feeder- No Sweat to Use! This picture above is simply a long and narrow trough filled with feed that chickens can access. Farmers may fill it themselves, or they can use a feed pusher that spreads out rations at programmed times. It is important to keep the feeder dry and clean so that it remains fresh and safe for consumption.

The farmers have to consider a few things while choosing broiler feeder They should first determine how many chickens they are supplying food for, and how much they require. This will help them to decide which size and type of feeders. They should also consider where they will place the feeder and if it is likely to be subjected to weather streams. They need to consider that the feeder fits into their pocket, of course. Chickens get much benefit from broiler feeders; the poultry rely on these to perform well and remain healthy. They also save time and money for the farmers.

Therefore, you have known enough about broiler feeders and why they are important to chicken farmers. It is everything to do with making sure every chicken gets exactly the amount of food it needs to grow up big and strong!

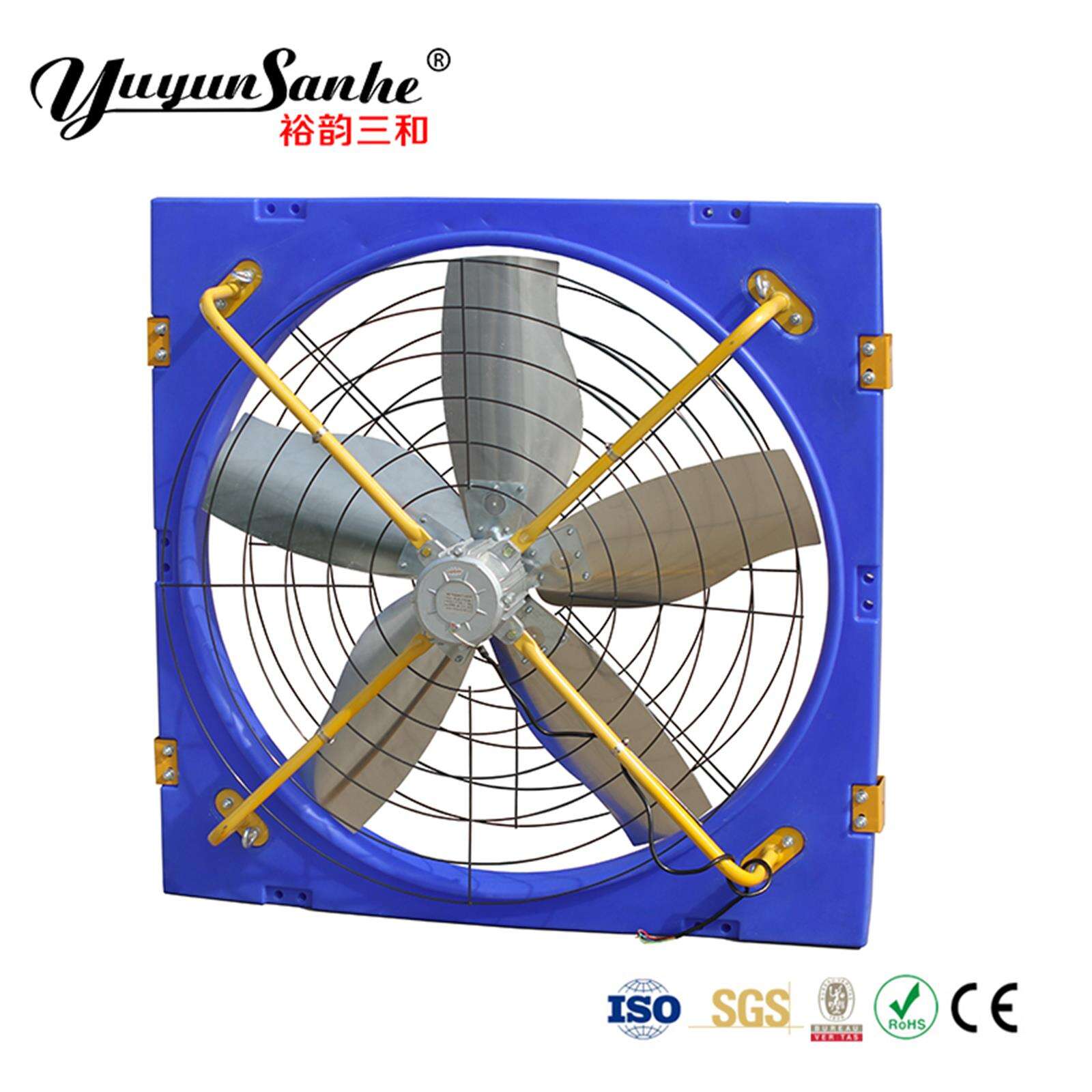

Shandong Yuyun Snhe Machinery Co., Ltd. is the nation's broiler feeder of ventilation and cooling equipment. We have the most modern range of production equipments. every production machine is digital control. Additionally, the accuracy of each procedure is required to be less than 0.03mm to ensure that interchangeability for our product parts is 100100. The majority of parts are produced by ourselves, reducing the cost of production while ensuring high-quality products, and leading the world in cost efficiency. We have a top design team with over 20 years of manufacturing and design experience. The products are all improved from production to drawing, from drawing to production and from improvement in drawing to mass production, to ensure that the percentage of defects is zero. We have a professional sales team that can effectively design the purchase plan for the customer, reduce transport expenses and boost customer profit margins. Our after-sales system gives our customers peace of mind. concerns.

All fan plates are constructed from hot dip galvanized sheets of 275g/m2, which we directly purchase from "broiler feeder" the most well-known Chinese steel manufacturer. This is not just a guarantee of the quality of our products, but also reduces the cost of production. Mitsuboshi belt is imported from Japan to ensure quality and long-lasting service. Krupp 430BA Stainless Steel blades, with an enormous air volume and great efficiency. No deformation, no dirt, stunning, durable. The 304 2B Stainless Steel Blades can be customized. Belt pulleys and flanges are constructed of high-strength aluminum and magnesium alloy by die-casting, light weight and vibration-free, as well as high strength and no breakage. All components are manufactured using CNC streamlined production, excellent quality control, attractive appearance leading the market. Yuyun Sanhe, Siemens, WEG, ABB, and WEG motors are readily available. The frequency and voltage can be adjusted.

broiler feeder company is equipped with the latest Feed Silo Production Equipment that is highly precise and automated. The body of the silo is made from 275g/m2 hot-dip-galvanized sheet, while the screws used are 8.8-level high-strength hot-dip galvanized bolts. These bolts are immune to oxidation, corrosion, and high temperatures, and have longevity and are able to withstand severe storms. The silo is comprised of the silo silo lid as well as the mounting ladder and the silo leg. The parts are manufactured using precision molds and advanced laser technology that is completely in line with the drawing design. They are then subjected quality checks in order to make them more consistent and precise.

We have a cooling pad production machine that is efficient and automation. The cooling pads we produce are corrugated in a uniform manner, have strong structural strength and are able to absorb water effectively. Corrugated paper is treated to provide excellent structural strength for corrosion resistance, anti-mildew properties and long service life. Water absorption and permeability are excellent with no water drift will ensure that water gets evenly through the entire wall of the cooling pad. The stereoscopic design provides the highest rate of evaporation for heat exchange between air and water. A broiler feeder as per standard, width of 600mm cooling pad requires more than 86 sheets. Frames made of aluminum frames, stainless steel frames, galvanized sheet frame, and PVC frames are all available.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802