Hello, friends! Cattle fans are something very interesting and I want to tell you about them today. Have you ever heard of cattle fans? The fan is a special type of air cooler that helps cows, horses and other animals to cool down during the heat in summer days raging under bright sun. Read on to find out more about cattle fans and how they keep our cows happy, comfortable,and healthy!

Cows Sweating like Humans And were you aware that cows can sweat too? It's true! Cows are also susceptible to heat stress as when it is too hot they find breathing difficult and feel uneasy even getting ill. This is the reason we need cattle fans. Turn these on, and they circulate fresh air around which is good for keeping the barn or field cool - this helps keep our animal friends a bit cooler too. ~ Cows like the air to be cooler as it makes them feel better and helps in relaxing just like we enjoy a cold breeze when its hot out.

Being comfortable is going to make them much happier and healthy cows. A cow that is happy, a tank of milk and barn-bred foal destined to mature into competition quality for years to come. We assist our animals to be more comfortable and enjoy their farms by using cattle fans. Keep in mind that a comfortable critter is more calm, relaxed & ultimately happy. Good health helps all young animals live up to the best of their potential, just like it does with us.

Farm fans provide choices for farmers to opt from, and there are several different kinds of farm fan. For diapers are very different from each other, and it is important to choose the correct type for your barn or field so that the animals feel comfortable. To decide which cattle fan is right for you consider barn size, number of animals and the climate at your location. And ensure that it is safe for the animals as well, so if they wander to close to it and harm won't befall them. A quality fan which does not risk hurting the animals can keep them cool.

And as we noted before, happy cows are simply better cows for farmers. Cows kept cool by cattle fans push out more milk and gain weight faster. This acreage would only need to be harvested 5,200 times and not sprayed at all which helps farmers make more money loosing less animals. It’s a win-win situation! Farmers could raise productive cows by giving them a comfortable environment, which is great mutual benefit for both sides. Happy and healthy animals make everyone happy!

Animals are number one and there is no debating that - cow fans take care of animals in a huge way. Cow cool-wearingFH/ non-hot-cow makers make cows dont to get hot so a cow with those will not have any health complicates in his life yet. When animals get sick from excessive heat, the result is never a good thing! Some would say cattle fans which help our animals to live a care free and happy life on the farm. They are one of many things we use to help make sure our feline and canine loved ones are well cared for.

We have a cooling pad production machine that is efficient and automation. The cooling pads we produce are corrugated in a uniform manner, have strong structural strength and are able to absorb water effectively. Corrugated paper is treated to provide excellent structural strength for corrosion resistance, anti-mildew properties and long service life. Water absorption and permeability are excellent with no water drift will ensure that water gets evenly through the entire wall of the cooling pad. The stereoscopic design provides the highest rate of evaporation for heat exchange between air and water. A cattle fan as per standard, width of 600mm cooling pad requires more than 86 sheets. Frames made of aluminum frames, stainless steel frames, galvanized sheet frame, and PVC frames are all available.

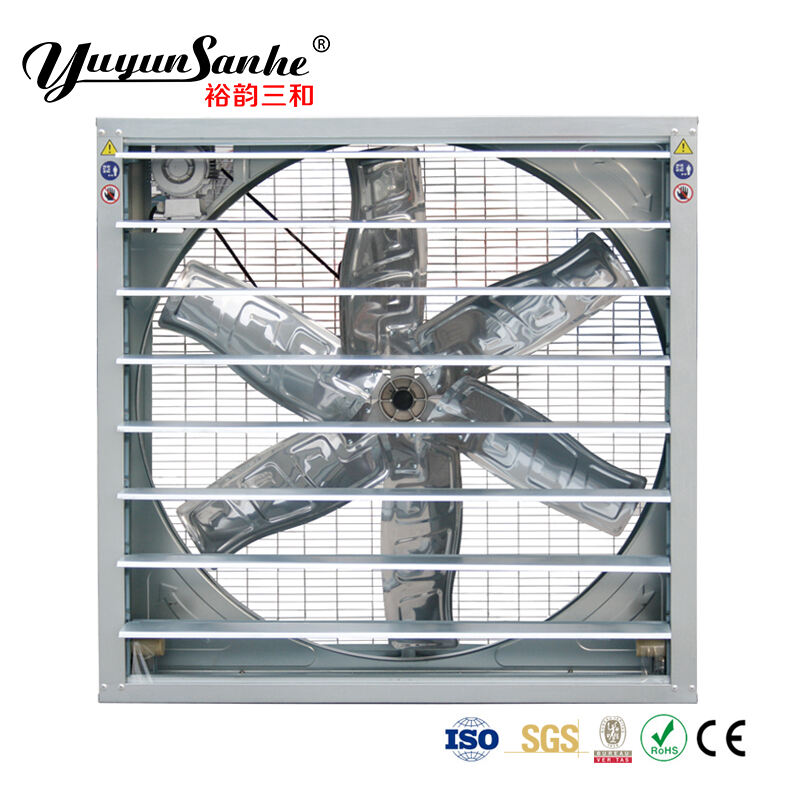

The fan plates are all composed of 275g/m2 hot-dip galvanized sheet. It is purchased from the famous Chinese steel company "Shougang Group" This does not just guarantee the quality of the product but also reduces production costs. Mitsuboshi belts are imported directly from Japan to ensure quality and lasting service. Blades materials are Krupp self-cleaning 430BA Stainless Steel, large air volume and high efficiency with no deformation and no dust, beautiful and sturdy. The cattle fan can be personalized. Flange and belt pulley are made of high-strength magnesium-aluminum alloy made by die casting, which is lightweight weight and vibration-free, as well as strong, and with no breakage. All components are made using CNC automated manufacturing, which guarantees the highest quality, attractive appearance, and a leading position in the market. Yuyun Sanhe motor, Siemens motor WEG motor and ABB motor are also available. Voltage and Frequency are customizable.

Shandong Yuyun Sanhe Machinery Co. is the largest domestic manufacturer of cooling and ventilation equipment, we have the most cattle fan of production equipment, all of which use digital control. Additionally, the errors of each process are restricted to less than 0.03mm to ensure that the interchangeability of our product parts is 100100. We manufacture 95% of our own components, which reduces production costs and assures the highest quality of product and is a leader in the industry in cost efficiency. We have a top design team, more than 20 years of expert production and design experience. Every product has been refined from drawing to production from drawing to production, and from drawing improvement to mass production to ensure that the rate of product defects is zero. Our sales professionals will help you plan your purchase for you, reduce transport costs and boost profit margins. The perfect after-sales support system let our customers no worry about their purchases.

Our company has a cattle fan Feed Silo Production Equipment that is highly precise and automated. The silo's body is constructed from 275g/m2 hot-dip-galvanized sheet, while the screws used are 8.8-level high-strength, hot-dip-galvanized bolts. These bolts are immune to corrosion, anti-oxidation and high temperatures, and have longevity and are strong enough to withstand extreme storms. The silo is composed of the silo, silo lid mounting ladder, silo leg. The parts are produced by using precise molds and the latest laser technology that is completely in line with the drawing. They are then subjected quality tests to make them more standard and accurate.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802