What is an air inlet louver? This is a classified item, with the help of which,supports in aiding air move over both ventilations systems. Air inlet louvers – There is no obstruction to the flow of air. So that the air can move and all your home… buildings will have nice clean breathing air.

Air inlet louvers are made to improve air flow and also save you money on your energy costs. As the system is not sucking as much air in to move around, since it would in a less airy world. Therefore, it is environmentally friendly and there also a saving on bill too. Moreover, we consume less energy at the same time as using our system under lower temperatures eventually which helps in keeping environment safe also apart from it saves a huge amount of cash and so air inlet louvers are assisting both for planet and pocket.

The HVAC system can operate better using the help of air inlet louvers. ADT401 Digital Thermometer measures temperature in Heating, Ventilation and Air Conditioning (HVAC)constituents. If air does not course appropriately it can impede the success of the system, causing a few strong signs in your computer. This can lead to issues like low air quality in the house, unbalanced airflow towards and away from various rooms, or high energy bills. This is also the reason why cooling towers are able to perform up to 40% better with air inlet louvers installed -- when it comes on and if all of its motors function correctly.

These are very necessary for industrial ventilation systems that is called air inlet louvers. A casual observer may wonder why is this relevant to the decision making process. They are used to prevent the damage of bulky fans and machines, and they save them. Because in industrial environments, equipment is extremely expensive and often needs the support of complex (and equally expensive) controls. You will not replace these very soon, so this investment here saves you from added repair and replacement costs in the coming time.

The air inlet louvers can be made of various materials but are predominantly aluminum or galvanized steel. These materials are strong and durable. This allows air to circulate through the soil while keeping dust or a small creature (or worse…bugs) from eating the content! So, it ensures the cleanliness and quality of air to keep you healthy and comfortable.

For what you need, there are different types of Air inlet louvers to choose from. Still others are called stationary louvers, as they neither move around nor need to be adjusted. These are some even have adjustable ports for you to regulate the air flow, making sure cold and wind do not reach your baby. This will save the vents and all of us having drainable louvers is nice as well No Water in Ventalation系统

They must also be cared for, including the fairings over tunable inlet louvers common on today's wings. Gates that are well-maintained will essentially last longer. Would you believe that we do daily checks and cleanings like this every month just to make sure it runs perfectly? They wear out with use and need to be replaced or your system will not perform efficiently.

Our company has a air inlet louver Feed Silo Production Equipment that is highly precise and automated. The silo's body is constructed from 275g/m2 hot-dip-galvanized sheet, while the screws used are 8.8-level high-strength, hot-dip-galvanized bolts. These bolts are immune to corrosion, anti-oxidation and high temperatures, and have longevity and are strong enough to withstand extreme storms. The silo is composed of the silo, silo lid mounting ladder, silo leg. The parts are produced by using precise molds and the latest laser technology that is completely in line with the drawing. They are then subjected quality tests to make them more standard and accurate.

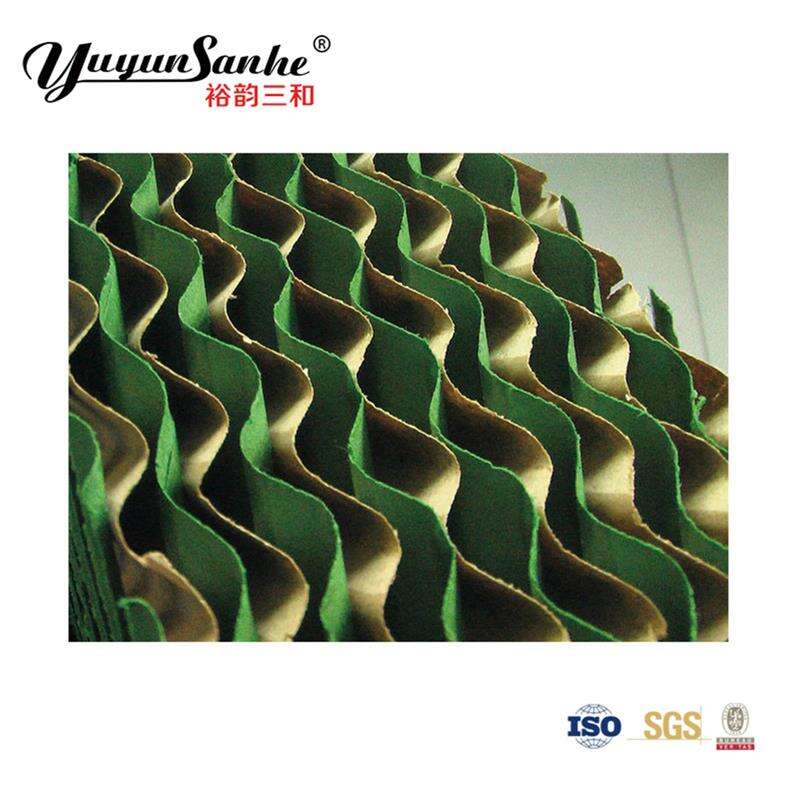

We have a air inlet louver manufacturing machine that is efficient and automation. The cooling pads produced are corrugated uniformly, have strong structural strength and can absorb water efficiently. The corrugated papers have been specially treated to have high durability and resistance to corrosion. It also resists mildew. Water absorption and permeability are excellent, no water drift, will ensure that water is evenly absorbed by the entire cooling pad wall. The stereoscopic design is specific and provides the biggest surface area for evaporation to exchange heat between water and air, the efficiency of evaporation is high. Safety Energy saving Environmental protection, cost-effective and applicable. Standard production 600mm wide cooling pad requires at least 86 sheets. Frames made of aluminum or stainless steel frame galvanized sheet frame and PVC frame are options.

The fan plates are all composed of 275g/m2 hot-dip galvanized sheet. It is purchased from the world-renowned air inlet louver "Shougang Group" that not only guarantees product quality but also cuts production costs. Mitsuboshi belt imported from Japan to ensure high-quality and service life. Krupp 430BA Stainless Steel blades, with an enormous air volume and great efficiency. No deformation, no dirt, beautiful and durable. The 304 2B Stainless Steel Blades can be personalized. Flange and belt pulley are constructed of high-strength aluminum and magnesium alloy through die-casting. It is light weight and vibration-free, as well as strong, and with no breakage. All parts are manufactured by CNC efficient manufacturing that guarantees the highest quality, attractive design and top of the line. Yuyun Sanhe, Siemens, WEG, ABB, and WEG motors are available. Voltage and Frequency can be changed.

Shandong Yuyun-Sanhe Machinery Co., Ltd. is the most renowned manufacturer in China of cooling and ventilation equipment. We have the most modern set of air inlet louver. all production equipment adopts digital control. The error for each process is limited to 0.03mm to ensure that interchangeability for our product components is 100100. We make 95% of our own components that reduces production costs, guarantees product quality and sets the standard in the world for cost performance. We have an amazing design team with over 20 years of design and production experience. To guarantee that we have zero defects the products have been developed at every stage of production, from sketch to the production, from the production to drawing, and finally by making improvements to the drawing, we can move onto mass production. Our expert sales team will plan your purchase for you, reducing costs for transport and improve profit margins. Our customers can be assured of a flawless after-sales service.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802