Are you wondering how special metal makes a fan work better? It all starts out with a wrought iron frame that is treated with a magical metal called galvanized steel to keep things strong. First, it begins as a fundamental steel, but then a specialty layer of zinc goes on top thanks to the workers. This zinc layer is like a barrier preventing rust and corrosion from breaking down the metal

YuyunSanhe is well-versed in crafting these unique fans. They make really strong exhaust fans that can be used in huge buildings like factories. Think of a fan that really will help to safely and quickly push bad air and smoke out of a room.

These are not the little fans you have at home. They are big and powerful. They play well with a lot of air and work at many locations. These special fans help clean and refresh the air in warehouses, large workspaces, and factories

The fans are designed to be robust. They can withstand hot days and cold days and continue to work. These fans are still doing their work when the weather changes. They do not lose their strength or rust easily because of the special metal they are made of. Thus, these fans can be used by the business owner for decades without concern.

They are very easy to clean these fans. A special zinc layer makes the metal less vulnerable to dirt or damage. Workers can simply wipe them down, and they will look good as new.” This makes them a good option for businesses looking for an effective, low-maintenance solution.

One of these fans’ best qualities is how hard they can work. All day, they can blow bad air out of large rooms. There are factories that have machines to generate smoke or unpleasant odors. Those fans help to ensure the air is clean and safe for workers.

YuyunSanhe produces fans that are the superheroes of the fan world. They are tough and strong, and always willing to help. If you want a fan that can really put in the hours and withstand the test of time, these are for you. These fans can get the job done from large factories to huge warehouses.

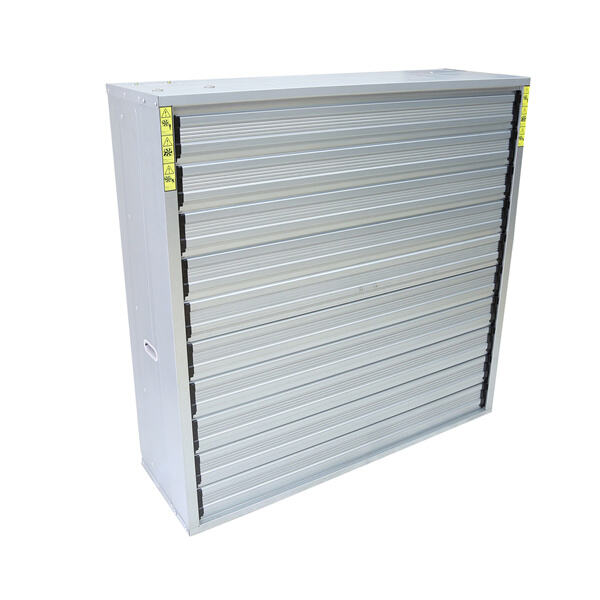

We have a cooling pad manufacturing machine that is Galvanized steel exhaust fan and automated. The cooling pads that are produced are uniformly corrugated, possess strong structural strength and are well able to adsorb water. The corrugated paper is specifically treated to provide high structural strength and corrosion resistance. It also has a resistance to mildew. Water can penetrate the entire surface of the cooling pad, thanks to adequate permeability, water absorption and zero water drift. The stereoscopic design allows the greatest evaporation rate heat exchange between water and air. Standard production, 600mm wide cooling pad requires an 86-sheet frame. Frames made of aluminum frames, stainless steel frames, galvanized sheet frame and PVC frame are available.

Shandong Yuyun-Sanhe Machinery Co., Ltd. We are the top domestic manufacturer of ventilation equipment. Our manufacturing equipment is digitally controlled, and we require that each error is less than 0.03mm so that we can guarantee an absolute interchangeability. More than Galvanized steel exhaust fan of our components are manufactured by us, reducing the cost of manufacturing as well as ensuring quality product, and leading the world in price performance. Our design team is super-efficient and has more than 20 professional years of production and design know-how. All products have been improved from drawing to production from production to drawing, and from drawing improvement to mass production to ensure that the percentage of defects is zero. Our professional sales team will design your purchase for you, reduce transport costs and increase profits. The perfect after-sales support system let our customers no worry about their purchases.

The fan plates are all composed of 275g/m2 hot-dip galvanized sheet. It is purchased from the world-renowned Galvanized steel exhaust fan "Shougang Group" that not only guarantees product quality but also cuts production costs. Mitsuboshi belt imported from Japan to ensure high-quality and service life. Krupp 430BA Stainless Steel blades, with an enormous air volume and great efficiency. No deformation, no dirt, beautiful and durable. The 304 2B Stainless Steel Blades can be personalized. Flange and belt pulley are constructed of high-strength aluminum and magnesium alloy through die-casting. It is light weight and vibration-free, as well as strong, and with no breakage. All parts are manufactured by CNC efficient manufacturing that guarantees the highest quality, attractive design and top of the line. Yuyun Sanhe, Siemens, WEG, ABB, and WEG motors are available. Voltage and Frequency can be changed.

Our Galvanized steel exhaust fan offers the most modern Feed Silo Production Equipment with high production automation and high precision. The body of the silo is made of 275g/m2 hot-dip galvanized sheet while the screws used are 8.8-level, high-strength, hot-dip-galvanized bolts. These bolts are immune to corrosion, anti-oxidation and high temperatures. They also have an extended life span and are capable of enduring extreme storms. The feed silo is mainly composed of silo body, silo cover, mounting ladder and silo legs, etc. The parts are produced using high-quality molds, precision tools and laser technology in complete compliance with the drawing design. They then undergo rigorous quality tests to make them more standard and accurate.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802