Do you grow plants in your greenhouse? If yes, then you must know that summer is a real heck of hot! Temperatures inside the greenhouse can get so warm that your plants may be in pain, stunting their growth and making it particularly hard to grow them large and sturdy. But don’t worry! Cooling pads for Greenhouse: A simple solution to this problem

I wanted to cover greenhouse cooling pads-Green and hearty way of keeping your green house cool when it is hot outside. Evaporative coolers are used to draw warm air through the cooling pad and push out a fresh, cooler air being circulated around inside the greenhouse. The water in the pad will evaporate and this process keep air cool, help to regulate temperature, make inside greenhouse more comfortable for plants.

A greenhouse cooling pad will enable you to maintain the ideal temperature inside your greenhouse even during those scorching summer days. Moisture is another hallmark ingredient when you are trying to get any plant to grow strong and healthy. If it gets too hot for the plant, it may go limp and even get a disease. Cooling pads also help prevent pests and diseases that thrive in warm, damp environments. By doing this, you are helping your greenhouse stay cool enough for vegetables without cooked them.

A greenhouse cooling pad is an efficient solution for a better control of the internal climate in your greenhouse. It is far cheaper to run air conditioning and also uses less electricity which ultimately helps the environment as well. It is very good in cooling the air and your plants become more happy so they can grow properly.

What is the best way for you to save money on your electric bill if not using a greenhouse cooling pad. It Consumes Much Less Power than Air Conditioner, So you can enjoy the cool air for longer period of time without any worries about electricity bill. And if you want to plant some extra plants or get a new garden pot, more money for them! Again, though, bear in mind that cooling pads tend not to work well when the climate is very humid.

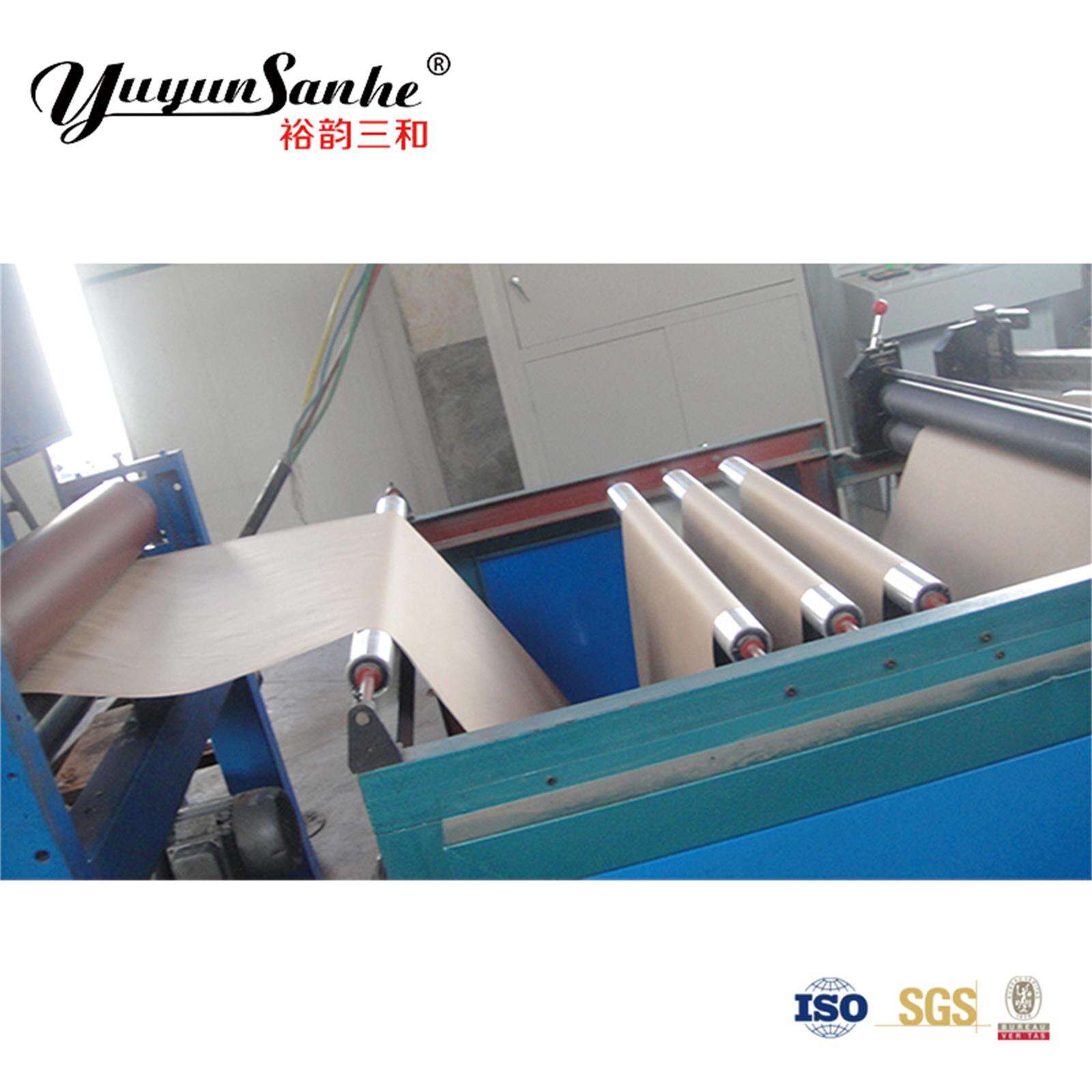

Our company is equipped with the latest Cooling Pad Production Machine, precise computer control high automation, greenhouse evaporative cooling pad in production, the output cooling pad features uniform corrugation, high structural strength and good water absorption. Corrugated paper is processed, and has strong structural strength and corrosion resistance, as well as mildew resistance and long service life. Absorption of water and permeability with no water drift can guarantee that water flows evenly across the entire cooling pad wall. Specific stereoscopic structure provides the biggest surface area for evaporation to exchange heat between water and air, evaporation efficiency is high. Safety and energy savings environmentally friendly, economical and practical. Standard production 600mm wide cooling pad requires 86 sheets. Frames made from aluminum, galvanized steel, stainless steel as well as PVC can be found.

Our company is greenhouse evaporative cooling pad with the latest Feed Silo Production Equipment with high production automation and high precision. The silo is composed of 275g/m2 hot-dip galvanized sheet. All screws are made from 8.8-level high-strength hot-dip galvanized bolts that are resistant to corrosion, anti-oxidation, high-temperature resistance and high strength, long service life, and can withstand a hefty storm. The silo consists of the silo, silo lid, mounting ladder and silo leg. Each component is manufactured strictly in accordance with drawing design by using advanced lasers and molds that are precision which are then subjected to rigorous quality inspections to make each element more standard, more precise in size, and more convenient to install to ensure easy installation and operation.

Shandong Yuyun-Sanhe Machinery Co., Ltd. We are the leading domestic manufacturer of equipment for ventilation. Our manufacturing equipment is digitally controlled, and we insist that each error be less than greenhouse evaporative cooling pad to ensure an absolute interchangeability. We produce 95% of our own parts that reduces production costs, guarantees product quality and sets the standard in the way in cost-performance. We have a super design team with over 20 years of design and production experience. To ensure zero defect rates All products have been developed at every stage of production, from drawing stage to production, from production to drawing, and finally after drawing improvements, to mass production. Our experienced sales staff will help you plan your purchase for you, reduce transport costs and improve profits. And the perfect after-sales service system allows our customers to have no worries.

The fan plates are all composed of greenhouse evaporative cooling pad hot-dip galvanized sheet. It is directly bought from the renowned Chinese steel manufacturer "Shougang Group" This not only guarantees product quality but also cuts production costs. Mitsuboshi belt is directly imported from Japan for its high-quality and long-lasting service. Blades material is Krupp self-cleaning 430BA Stainless Steel, large air volume with high efficiency and no deformation, so no dust, gorgeous and durable. 304 2B Stainless Steel Blades can be custom-made. Die-casting creates belt pulleys and flanges made from high-strength alloys of magnesium and aluminium. They are lightweight, have low vibration, high strength, and will not break. All parts are produced by CNC efficient production, gorgeous appearance, quality assurance and are among the top in the market. Yuyun Sanhe motor, Siemens motor WEG motor, ABB motor are optional. Voltage and Frequency are customizable.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802