Do you ever get hot-sticky from the summer sun? If so, you may want to consider using a cellulose evaporative cooling pad. While these pads are good for lowering the temperature and make you feel fresh during those scorching summer days. Today we will tell you about what cooling pads are, how they function and why this might be very useful for yourself as well as your home.

The air is cooled as it passes through cellulose evaporative cooling pads. They are doing it, by natural evaporation. Water evaporates from liquid to vapor and as we all learned in science class, helps cool the air around it. They function by taking in water and also when warm air actions with the wet pads, it is cooled off down to generate a great cools that can make you really feel extra comfy.

Save Cellulose Evaporative Cooling Pads — There are several different reasons why you should use cellulose evaporative cooling pads. Well first off — THEYRE MADE OUT OF NATURAL, ECO FRIENDLY MATERIALS SO THAT HELPS OUR ENVIRONMENT! When you use them, this means that you are looking after our planet. Second, they are energy-efficient and do not require a lot of electricity to run leading once again toward cost savings on your utility bills. On top of that, they do well in cooling small to medium-sized rooms when you are at home or office.

The installation of cellulose evaporative cooling pads is not a difficult task either. For the most part those will come with step by step instructions that are reall easy to follow. First you need to attach one end of the cooling pad with your tap or water tank wherefrom it will draw chilling water and wire up other via plug. Now connect everything, Power UP and you will see that the cooling pad starts to work (and cool of course).

Now, this is something you must keep in mind if your cooling pad is to do its job properly. You want to get rid of dirt and debris that can reduce its optimum level. An additional tip: washing the pad from time to time will keep it working well, and getting new ones if they are outdated or overused is also advised. Maintaining the item helps ensure that your cooling pad will last you for an extended period and give back to producing cool air this summer.

This is a very different way of operating from the traditional air conditioning systems that have been in place over many years, and it has one central component: cellulose evaporative cooling pads. Because air conditioners are designed to be hot, they will use a significant amount of electricity in the refrigeration process which can lead you with very high electricity bill at end of month that is why most people who service their AC units have noticed reduced energy consumption after a while. On the other hand, more power is used with evaporative cooling pads which are less efficient and energy-hungry. It allows your to be cool without cooling down everything (and worrying about the price).

So long as pads like cellulose evaporative cooling are convenient, the future indeed seems promising! As everyone is aware, it takes a lot of energy to stay cool in the summertime between air-conditioning and refrigeration. These requirements get answered by these cooling pads perfectly. They are growing in popularity among homeowners, business owners and even on an industrial site because they provide many advantages. With the advancement in technology, these cooling pads are getting more efficient and environment-friendly which makes them a better choice for having cool air indoors.

Our cellulose evaporative cooling pad offers the most modern Feed Silo Production Equipment with high production automation and high precision. The body of the silo is made of 275g/m2 hot-dip galvanized sheet while the screws used are 8.8-level, high-strength, hot-dip-galvanized bolts. These bolts are immune to corrosion, anti-oxidation and high temperatures. They also have an extended life span and are capable of enduring extreme storms. The feed silo is mainly composed of silo body, silo cover, mounting ladder and silo legs, etc. The parts are produced using high-quality molds, precision tools and laser technology in complete compliance with the drawing design. They then undergo rigorous quality tests to make them more standard and accurate.

All fan plates are constructed from hot dip galvanized sheets of 275g/m2, which we directly purchase from "cellulose evaporative cooling pad" the most well-known Chinese steel manufacturer. This is not just a guarantee of the quality of our products, but also reduces the cost of production. Mitsuboshi belt is imported from Japan to ensure quality and long-lasting service. Krupp 430BA Stainless Steel blades, with an enormous air volume and great efficiency. No deformation, no dirt, stunning, durable. The 304 2B Stainless Steel Blades can be customized. Belt pulleys and flanges are constructed of high-strength aluminum and magnesium alloy by die-casting, light weight and vibration-free, as well as high strength and no breakage. All components are manufactured using CNC streamlined production, excellent quality control, attractive appearance leading the market. Yuyun Sanhe, Siemens, WEG, ABB, and WEG motors are readily available. The frequency and voltage can be adjusted.

Shandong Yuyun-Sanhe Machinery Co., Ltd. We are the top cellulose evaporative cooling pad of ventilation equipment. Our production equipment is controlled digitally and we require that each error be less than 0.03mm to ensure an absolute interchangeability. About 95% of the components are manufactured by us which reduces the cost of manufacturing and ensuring the quality of the product and setting the standard for cost performance. We have a highly skilled design team with over 20 years of expert design and production experience. To guarantee zero defects All products have been developed at every stage of production, from sketch to the production, from the process to a drawing, and finally by making improvements to the drawing, we can move onto mass production. Our sales team who can efficiently design the purchase plan for the customer, reduce transport costs and boost profit margins. The perfect after-sales support system will leave our customers with no worries.

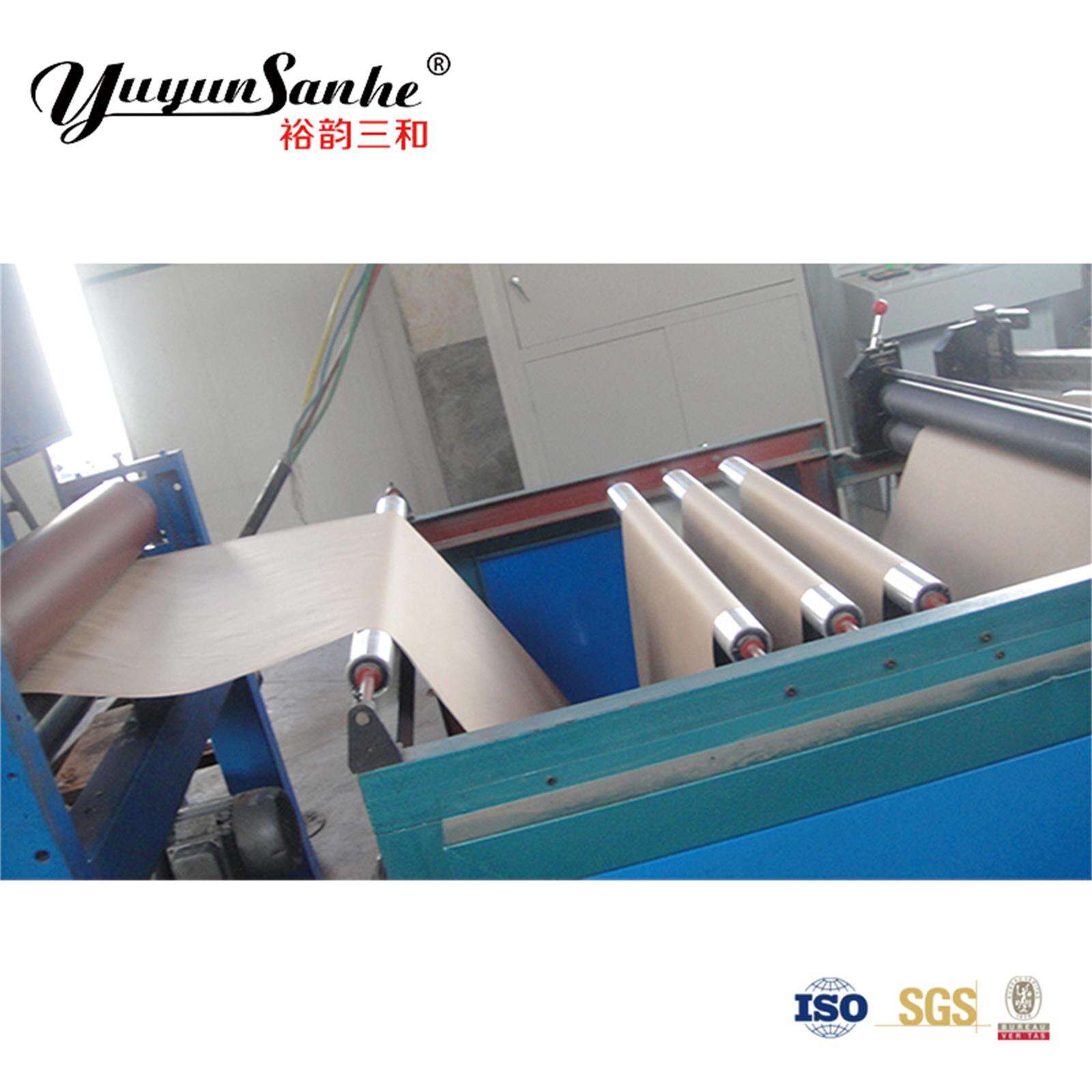

We have a cooling pad production machine that is efficient and automation. The cooling pads we produce are corrugated in a uniform manner, have strong structural strength and are able to absorb water effectively. Corrugated paper is treated to provide excellent structural strength for corrosion resistance, anti-mildew properties and long service life. Water absorption and permeability are excellent with no water drift will ensure that water gets evenly through the entire wall of the cooling pad. The stereoscopic design provides the highest rate of evaporation for heat exchange between air and water. A cellulose evaporative cooling pad as per standard, width of 600mm cooling pad requires more than 86 sheets. Frames made of aluminum frames, stainless steel frames, galvanized sheet frame, and PVC frames are all available.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802