محیط، اهمیت دارد. خوراکی دامها اغلب در کارخانههایی دیده میشوند که محصولات در آن تولید میشود، انبارهايی که انواع کالاها را نگهداری میکنند و حتی کارگاههایی که در آن موارد توسط کارگران ساخته میشود- تولیدکنندگان فان پلاگ.

به علاوه از خنک کردن منطقه، فانهای هواخیز صنعتی دیوارها را خشک و گرم نیز نگه میدارند. تغذیه خودکار خصوصاً در مناطقی مانند محیط کار ماشینآلات قطار لولهکشی که میتواند مقدار زیادی گرما تولید کند یا در نزدیکی مواد شیمیایی مضر که بوی بد و دود آلوده تولید میکنند، بسیار حیاتی است. فانهای هوا خروجی به کارگران کمک میکند تا هوا تازه بخورند و بنابراین سالمتر احساس کنند.

این فانها بیوقفه کار میکنند تا احکام سمی داخلی را خارج کنند، به طوری که همه افراد درون و بیرون امن باشند. GM: تجهیزات مزرعه پرندگان پیشنهاد هوشمندی بود برای دلایل بهداشت و ایمنی، با تمام آن مواد شیمیایی مضر از جمله مواد شیمیایی خطرناک، وقتی اینطور میگویید که نفس کشیدن چیزی خوب است، آنگاه سیستمهای Ventilation مؤثر دیگر اختیاری نیستند بلکه ضروری هستند.

این کمک میکند تا هواي استفهام از مکانهایی مثل آشپزخانهها و حمامات با کارایی عالی خارج و تخلیه شود و هواي تازه و تمیز از بیرون وارد شود. این stantiateViewController برای مرغ قوی مهم است زیرا این کار بهبود محیط برای همه افراد داخلی را تسهیل می کند و منجر به محیط کار سالم و پرآزمون می شود.

کارگران در حضور فان عادم صنعتی در محیط کار خود بهتر عمل می کنند. خوراکی جانوران مربوط به ایجاد راحتی نه تنها برای کارگران بلکه کمک به آنها در تمرکز بر جمعبندیهای خود است، ممنون به هواي قابل نفس زدن و نورپردازی مناسب.

شرکت ما دارای ماشین تولید پد خنککننده پیشرفته است، که با کنترل دقیق کامپیوتری، سطح بالای اتوماسیون و کارایی در تولید را دارد. پد خنک شده حاصل از این ماشین دارای ویژگیهای فان هواخیز صنعتی، قوی بودن ساختاری و ظرفیت جذب آب بالا میباشد. کاغذهای چرمی به طور خاص برای داشتن کیفیت و مقاومت بالا تیمار شدهاند و علاوه بر مقاومت در برابر فساد، ضد قارچ نیز هستند. جذب آب و نفوذ آن عالی است و بدون شناور شدن آب، اطمینان میدهد که آب به طور مساوی توسط تمام دیوارهای پد خنک کننده جذب میشود. طراحی سه بعدی، بیشترین نرخ تبخیر را برای تعویض حرارت بین هوا و آب ارائه میدهد. بر اساس طول استاندارد 600 میلیمتر، پد خنک کننده شامل بیش از 86 برگ است. گوشوارهها از آلومینیوم، فولاد ریزه شده، چدنی گالوانایز شده و PVC در اختیار مشتریان قرار دارد.

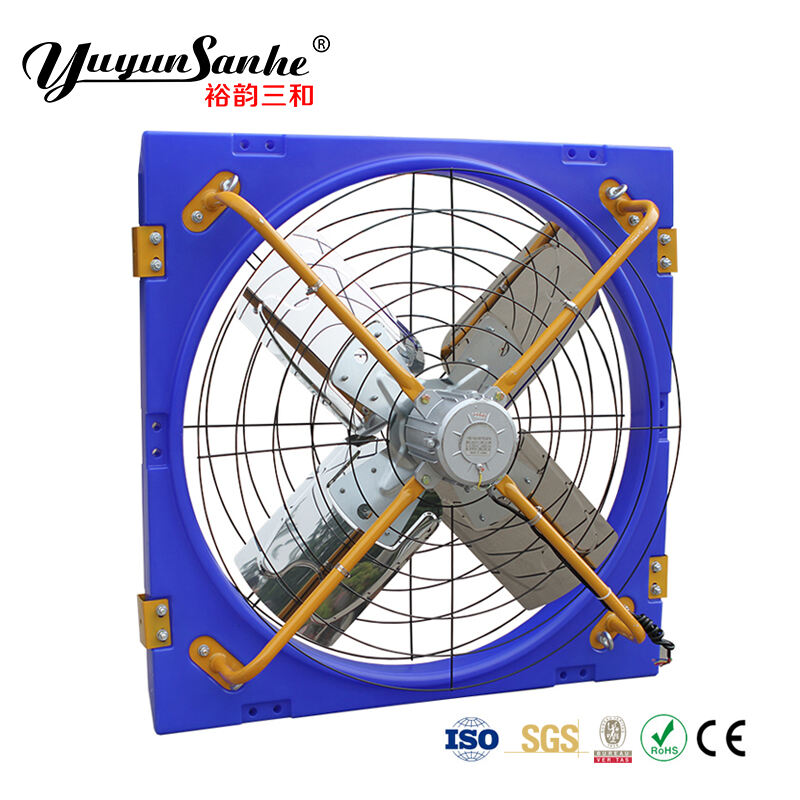

تمام صفحات فن بلواyers از فولاد 275g/m^2 مخصوص فن های خارج کننده صنعتی ساخته شده است. این محصول مستقیماً از شرکت فولاد معروف چینی "Shougang Group" خریداری میشود که علاوه بر تضمین کیفیت محصول، کمک میکند به کاهش هزینههای تولید. باند Mitsuboshi از ژاپن وارد شده است تا کیفیت بالا و طولانی بودن زمان خدمات را تضمین کند. پرهای فولاد راست نگین Krupp 430BA با حجم هوای بزرگ و کارایی بالا، دچار تغییر شکل نمیشوند، آلوده نمیشوند، زیبا و محکم هستند. پرهای فولاد راست نگین 304 2B نیز قابل سفارش هستند. چرخهای دندهای و لُحاف از آلیاژهای مقاوم شامل مگنز و آلومینیوم ساخته شدهاند که سبک هستند، ارتعاش کمی دارند، قوی هستند و نشکننده هستند. تمام مونتاژ با استفاده از تجهیزات CNC خودکار انجام میشود که کیفیت بالا، ظاهر شگفتانگیز و موقعیت رهبری در بازار را تضمین میکند. موتور Yuyun Sanhe، موتور Siemens، موتور WEG و موتور ABB در اختیار شماست. ولتاژ و فرکانس قابل تنظیم است.

شرکت ماشینآلات شاندونگ یویون سانه، تولیدکننده پیشروی کشور در تجهیزات تهویه است. تجهیزات تولیدی ما بهصورت دیجیتالی کنترل میشوند و ما بر این باوریم که خطای هر قطعه باید کمتر از ۰٫۰۳ میلیمتر باشد تا قابلیت جایگزینی کامل محصولات ما تضمین گردد. ما ۹۵ درصد قطعات خود را بهصورت داخلی تولید میکنیم که این امر هزینه تولید را کاهش داده، کیفیت محصولات را تضمین نموده و ما را در زمینه نسبت هزینه به عملکرد پیشتاز میسازد. تیم طراحی برجسته ما از بیش از ۲۰ متخصص با سابقه طولانی در طراحی و ساخت فنهای صنعتی برای خروج هوای آلوده تشکیل شده است. برای اطمینان از عدم وجود هرگونه عیب، تمامی محصولات در هر مرحله از فرآیند تولید — از تهیه نقشه تا تولید، از تولید تا بازبینی نقشه، و در نهایت با اعمال بهبودهای لازم در نقشه — مورد ارزیابی و بهبود قرار گرفتهاند تا بتوانیم به تولید انبوه برسیم. کارشناسان فروش حرفهای ما قادرند طرح خرید مناسبی را برای مشتریان تدوین کرده، هزینههای حملونقل را کاهش داده و سودآوری مشتریان را افزایش دهند. سیستم کامل خدمات پس از فروش ما، آرامش کامل را برای مشتریان فراهم میکند.

شرکت تولیدکننده پنکههای صنعتی برای خروج دود مجهز به جدیدترین تجهیزات تولید سیلوی تغذیه است که از دقت بسیار بالا و خودکارسازی شده است. بدنه سیلو از ورق گالوانیزه غوطهوری گرم با وزن ۲۷۵ گرم بر مترمربع ساخته شده است، در حالی که پیچهای مورد استفاده، بولتهای گالوانیزه غوطهوری گرم با درجه استحکام ۸٫۸ هستند. این بولتها در برابر اکسیداسیون، خوردگی و دماهای بالا مقاوم بوده، دارای طول عمر بالا بوده و قادر به تحمل طوفانهای شدید میباشند. سیلو شامل درب سیلو، نردبان نصب و پایههای سیلو میشود. قطعات با استفاده از قالبهای دقیق و فناوری لیزر پیشرفته تولید میشوند که کاملاً مطابق با طرحهای ارائهشده است. سپس این قطعات تحت بازرسیهای کیفی قرار میگیرند تا یکنواختی و دقت آنها افزایش یابد.

صوفی دونگ

صوفی دونگ [email protected]

[email protected]  +86-13780857291

+86-13780857291 لورنا گائو

لورنا گائو [email protected]

[email protected]  +86-19806216802

+86-19806216802