Axial flow fans are critical machines used to aid in the transfer and transportation of air throughout various compartments. They are especially good at maintaining a cooler temperature in the home or building on hot days. In summer, you could really use the fans for temperature control as well.

Axial Flow Fan Fans in general operate by pulling the air from one side and forcing it out on other. This creates a strong airflow and is really great for keeping things cool or making the air circulate well. These fans are created to be extremely effective meaning that they can move a great deal of air rapidly while utilizing low degrees of power. Which allow them to save on electricity and meanwhile, maintain the temperature of given areas accurately.

In a lot of HVAC systems, axial flow fans are used centrally which means they basically do the heavy lifting. Fans inside air handling units also help transport the conditioned air, through an extensive network of ducts located throughout a home and into individual rooms. This is to ensure that one part of the building and other parts will tend not have a different temperature - this way it makes sure that the roofspace ventilation works. Uniform temperatures also contribute to greater comfort for those in spaces where they are the longest. It keeps sensitive equipment from overheating or getting too cold.

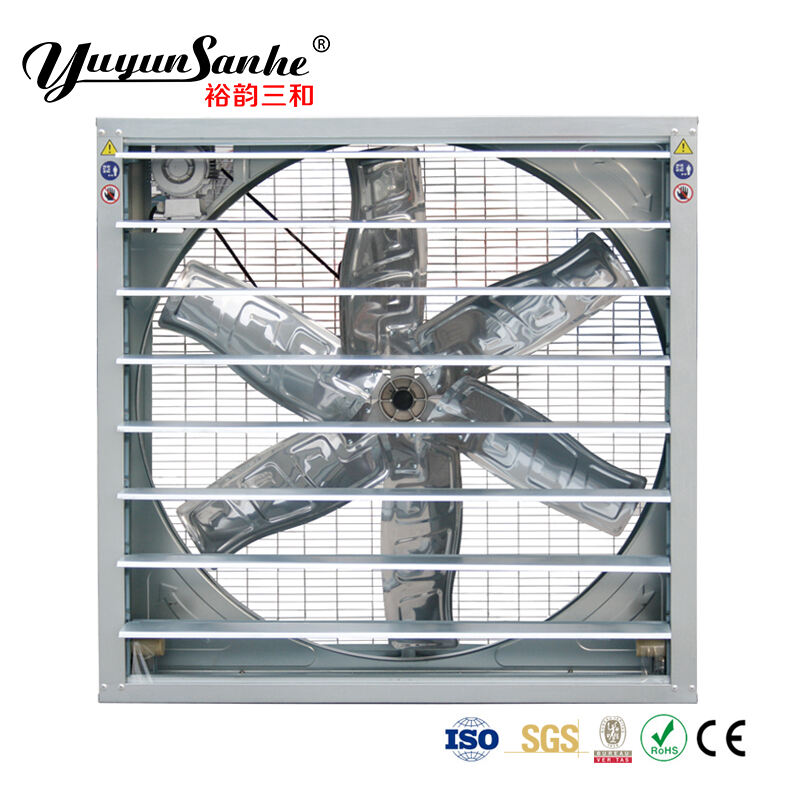

In addition to houses, they are also use on factories and large building in the axial flow fans which help control air an temperature. In environments such as these, it is important to keep clean and fresh air moving which helps contribute a safe & productive workplace. At times axial flow fans are provided with sturdy construction in order to make them work smoothly even during hard conditions. So this rigid construction makes them really long lasting, helping you use it for a longer period and not even in easily degradable conditions.

Benefits of Axial flow fans for cooling and air moving For instance, they are able to move lots of air rapidly and so play their part in keeping buildings fresh. Ventilation is important to eliminate musty odors and for fresh air. Another advantage is most of the time, these fans are pretty silent and can be used while you're sleeping or in other areas where loud noises could cause distractions. Therefore, these are good to be used at schools and even in offices or any peaceful environment.

Medium Axial Flow Fan : The axial flow fan is mostly known as low-pressure high volume medium air circulation fans. Its one of the top advantage that, its capability to produce a uniform and constant airflow. This feature is very useful in HVAC systems which must maintain a constant temperature. It means that when axial flow fans are used, they create smooth and even air. This predictability also comes makes it easier to keep a building an agreeable temperature for everybody inside.

axial flow fans We are the top domestic manufacturer of ventilation equipment. Our production equipment is controlled digitally and we require that each error be less than 0.03mm in order to guarantee an absolute interchangeability. The majority of parts we manufacture ourselves and reduce the cost of processing and ensuring the quality of the product and leading the world in price performance. Our design team is super-efficient and is comprised of more than 20 professionals with over 20 years of design and manufacturing knowledge. All products have been improved from drawing to production from drawing to production and from drawing improvement into mass production to make sure that the defect rate is zero. Our experienced sales staff can plan your purchase with you, reducing the cost of transport and boost profit margins. The perfect after-sales support system allows our customers to have no worry about their purchases.

The fan plates are all composed of axial flow fans hot-dip galvanized sheet. It is directly bought from the renowned Chinese steel manufacturer "Shougang Group" This not only guarantees product quality but also cuts production costs. Mitsuboshi belt is directly imported from Japan for its high-quality and long-lasting service. Blades material is Krupp self-cleaning 430BA Stainless Steel, large air volume with high efficiency and no deformation, so no dust, gorgeous and durable. 304 2B Stainless Steel Blades can be custom-made. Die-casting creates belt pulleys and flanges made from high-strength alloys of magnesium and aluminium. They are lightweight, have low vibration, high strength, and will not break. All parts are produced by CNC efficient production, gorgeous appearance, quality assurance and are among the top in the market. Yuyun Sanhe motor, Siemens motor WEG motor, ABB motor are optional. Voltage and Frequency are customizable.

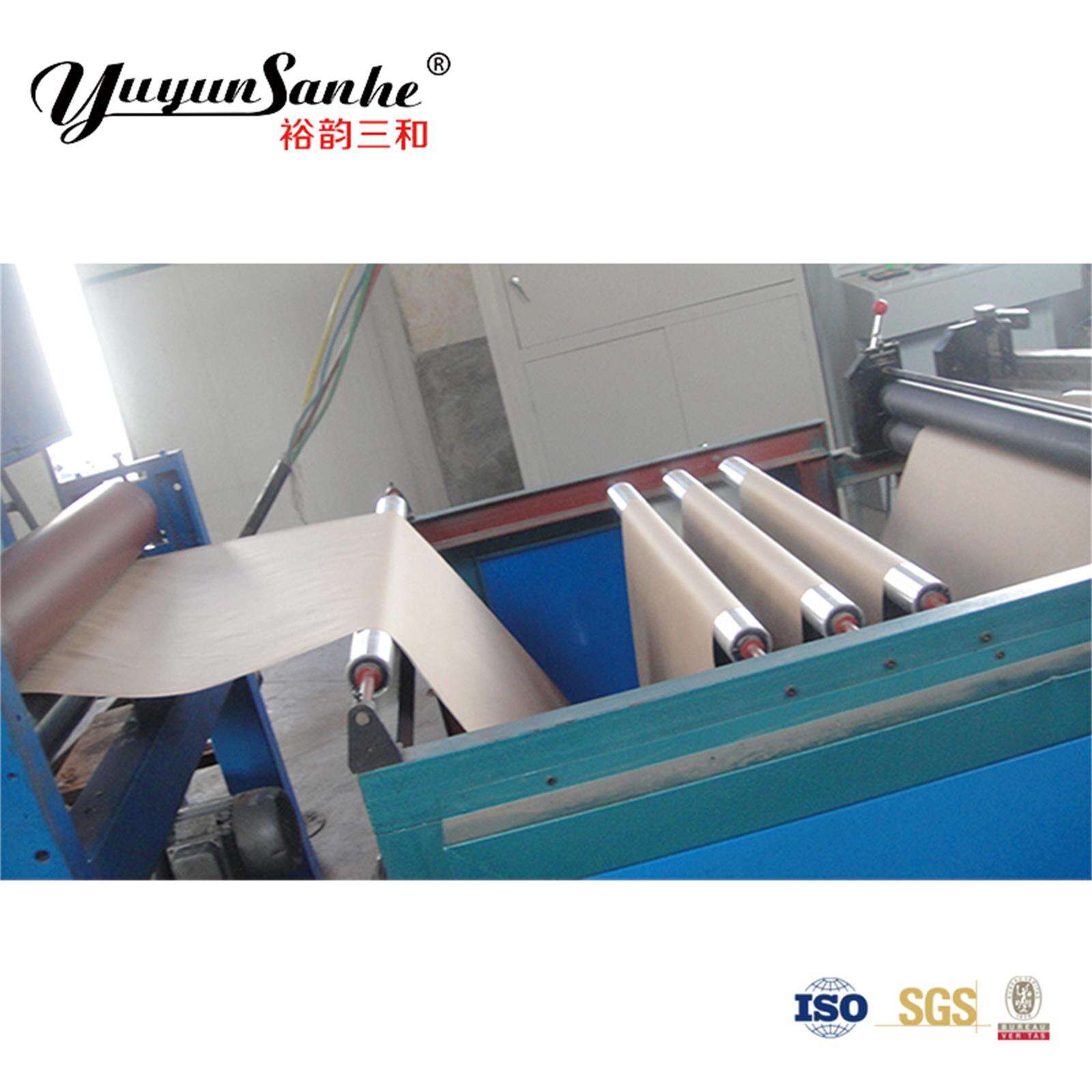

Our company owns a modern Cooling Pad Production Machine, precise computer control, high automation, high efficiency in production, the axial flow fans is uniform in corrugation and high structural strength and good water absorption. The corrugated paper is specially treated to have high durability and resistance to corrosion. It also has a resistance to mildew. Water can penetrate the entire surface of the cooling pad due to good permeability, water absorption, and zero water drift. Specific stereoscopic structure provides the largest evaporation surface area for the heat exchange between water and air, the efficiency of evaporation is high. Safety as well as energy efficiency Environmental protection, cost-effective and suitable. As per the standard size, 600mm cooling pad consists of an 86-sheet frame. Frames made of aluminum, stainless steel, galvanized sheet and PVC are also available.

axial flow fans company is equipped with the latest Feed Silo Production Equipment that is highly precise and automated. The body of the silo is made from 275g/m2 hot-dip-galvanized sheet, while the screws used are 8.8-level high-strength hot-dip galvanized bolts. These bolts are immune to oxidation, corrosion, and high temperatures, and have longevity and are able to withstand severe storms. The silo is comprised of the silo silo lid as well as the mounting ladder and the silo leg. The parts are manufactured using precision molds and advanced laser technology that is completely in line with the drawing design. They are then subjected quality checks in order to make them more consistent and precise.

Sophie Dong

Sophie Dong [email protected]

[email protected]  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao [email protected]

[email protected]  +86-19806216802

+86-19806216802